Stand:

Riyadh Cables Group

Stand:

Riyadh Cables Group

PARTICULARS & GUARANTEES RELATING TO PVC INSULATING COMPOUND (TYPE A)

Description

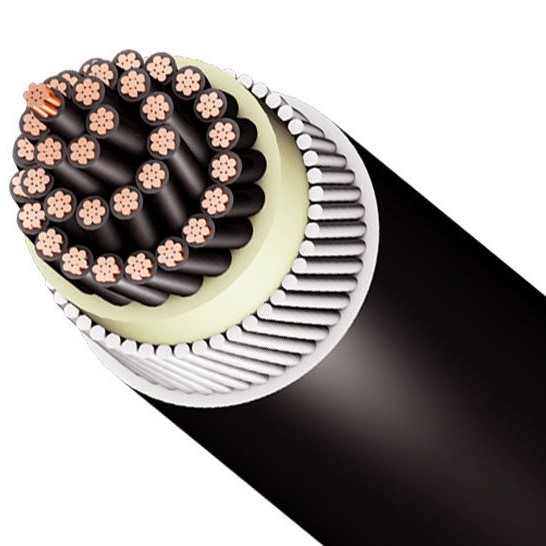

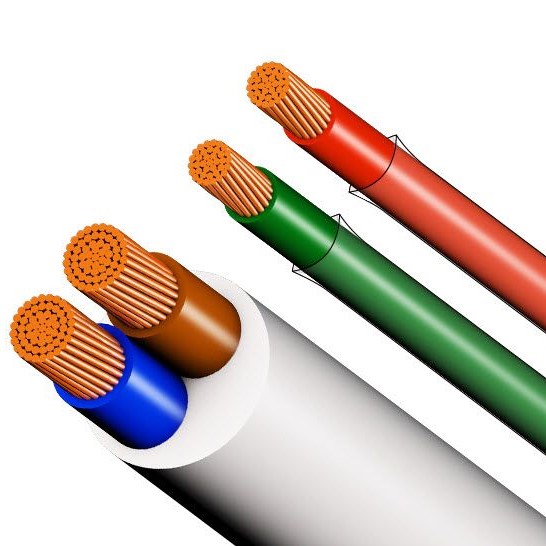

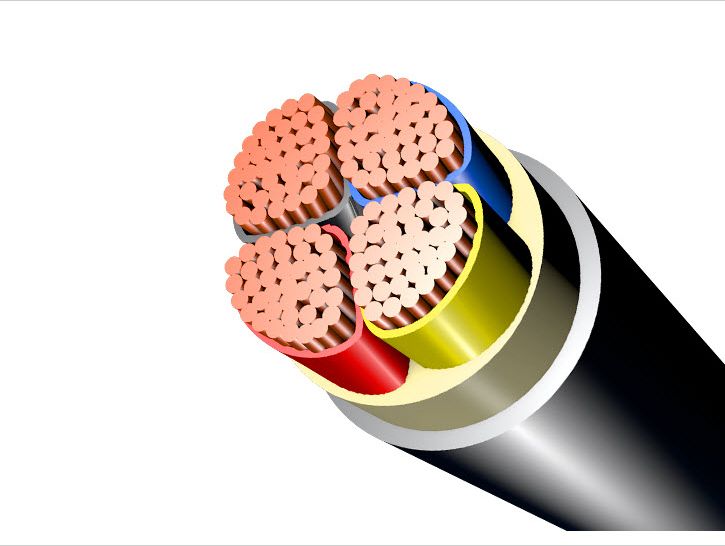

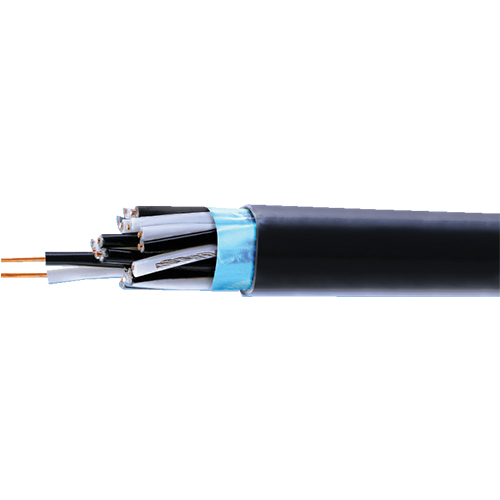

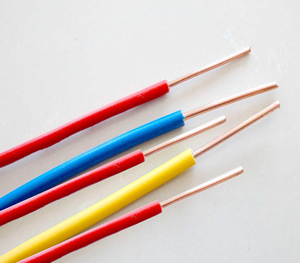

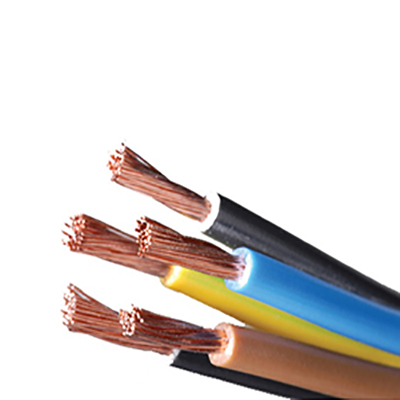

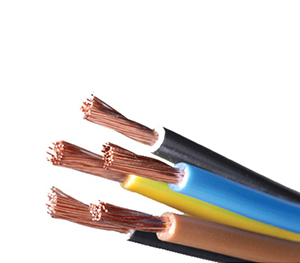

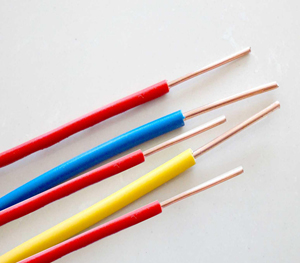

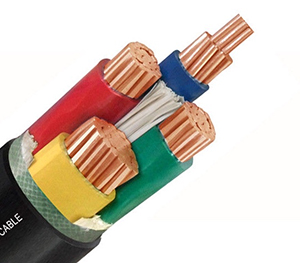

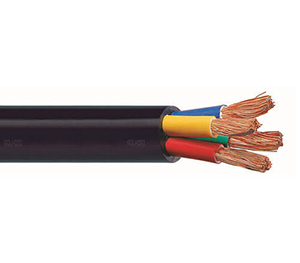

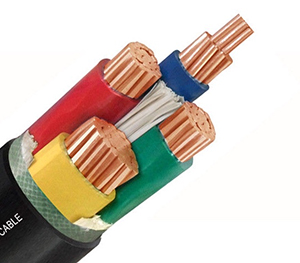

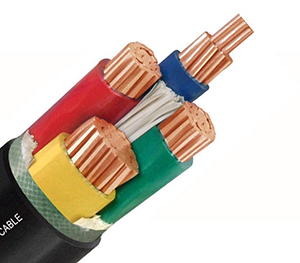

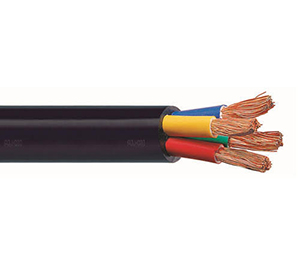

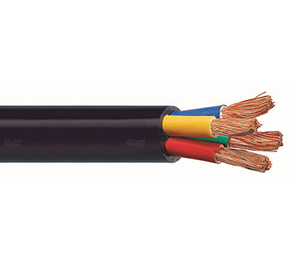

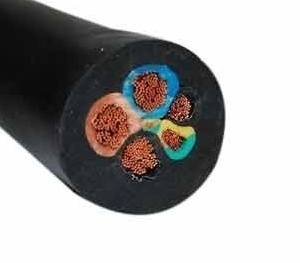

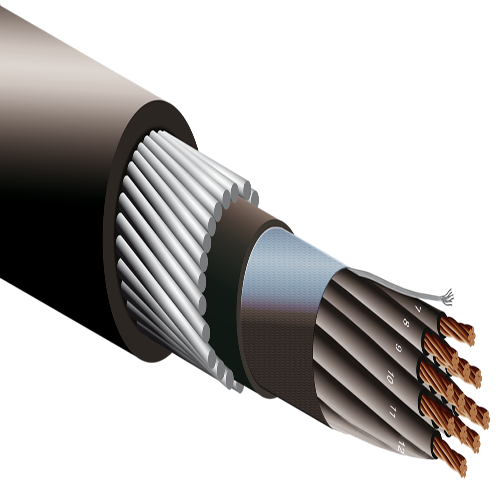

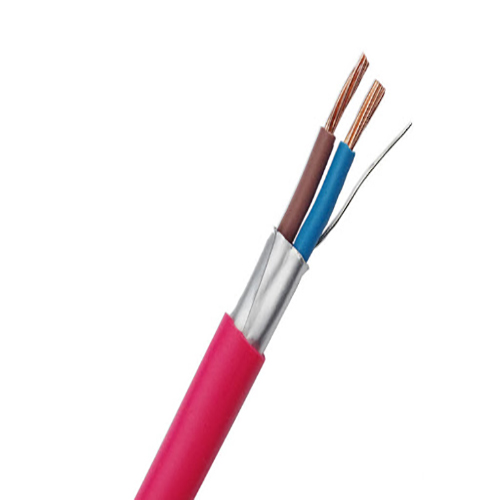

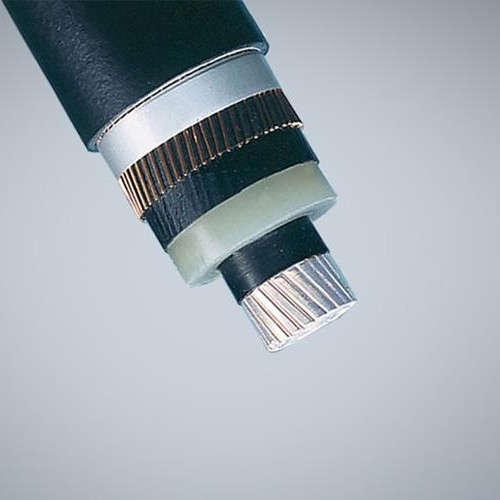

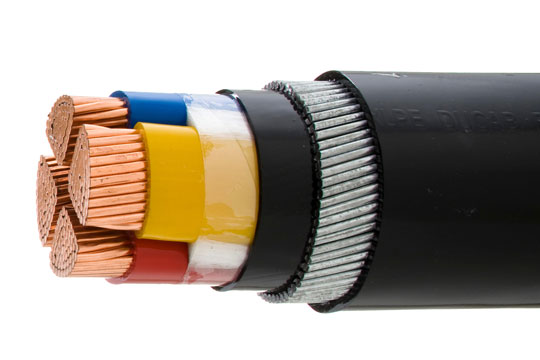

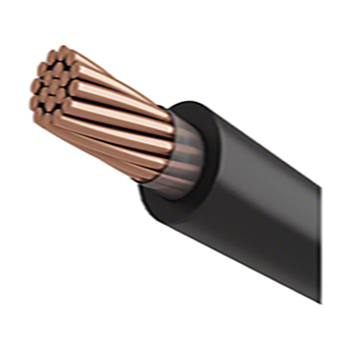

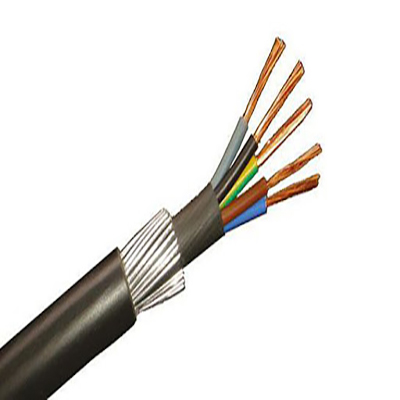

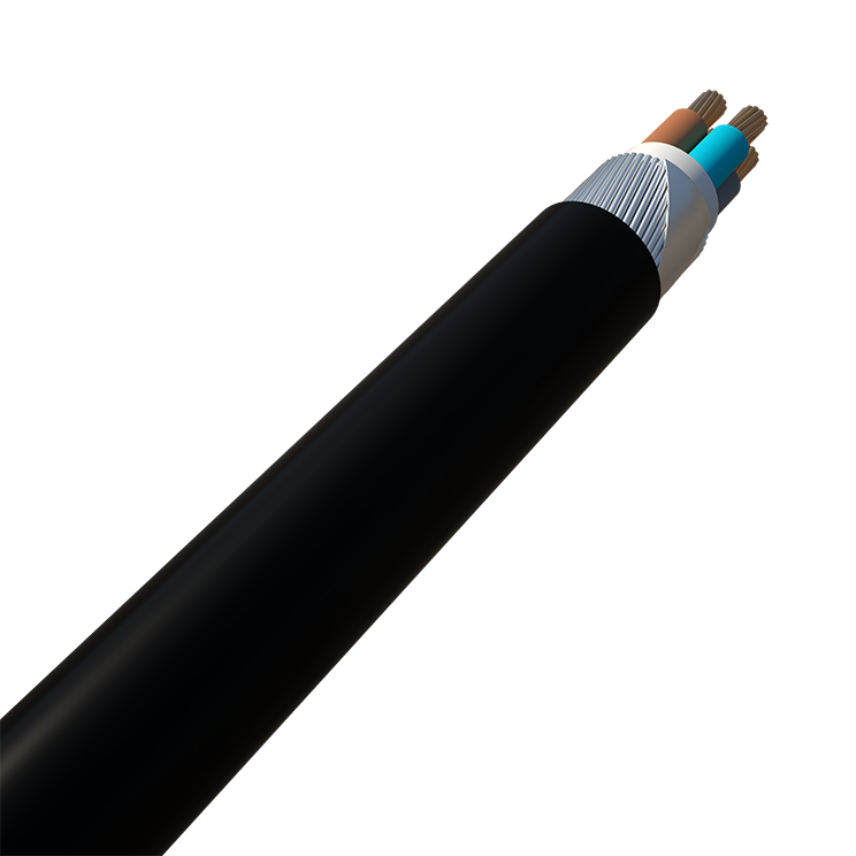

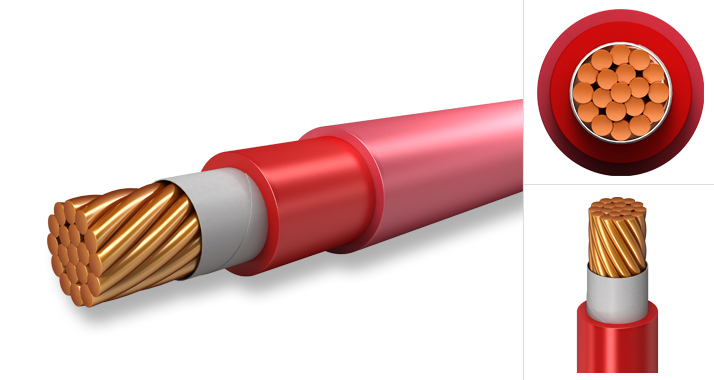

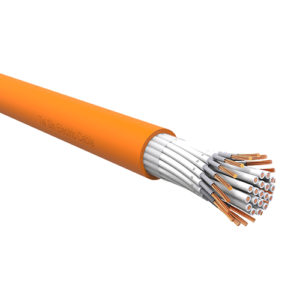

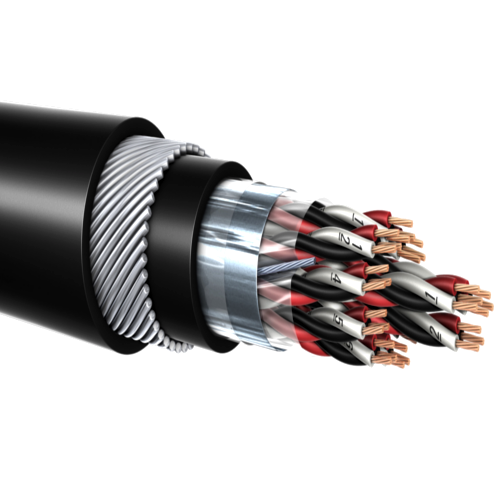

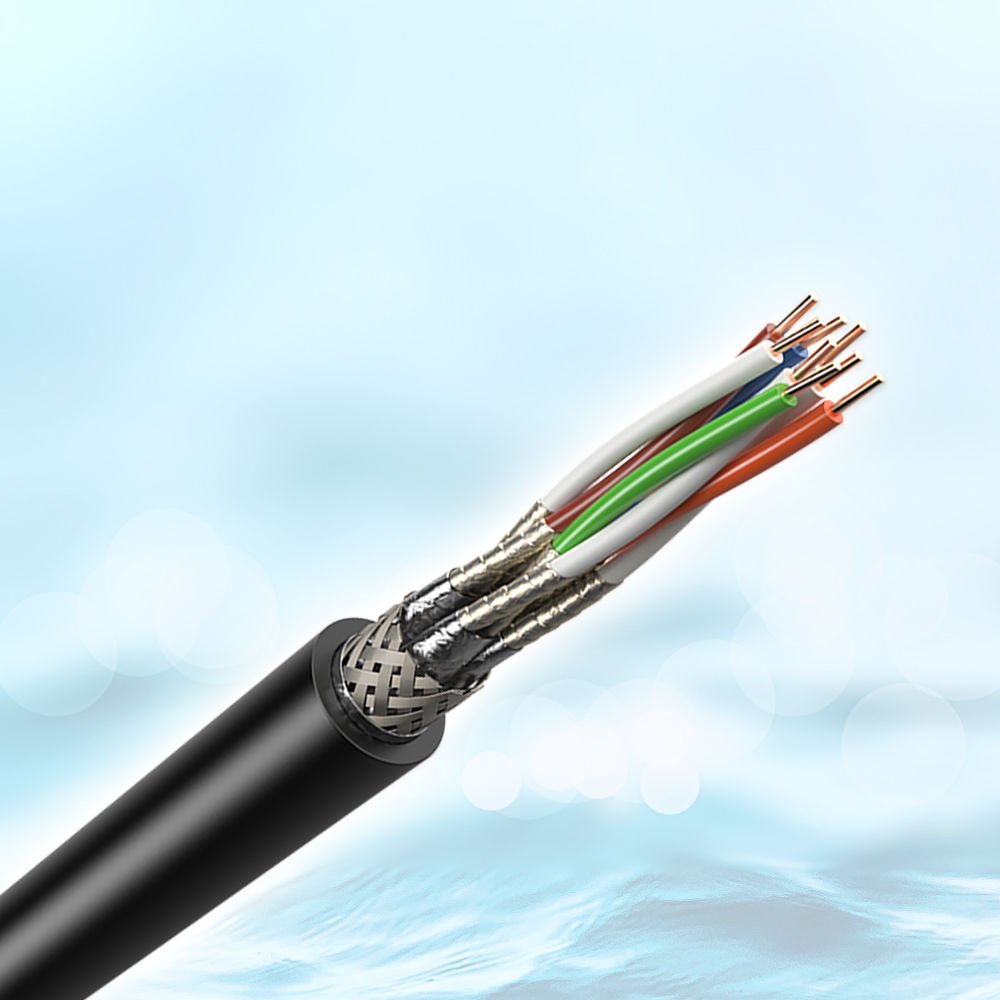

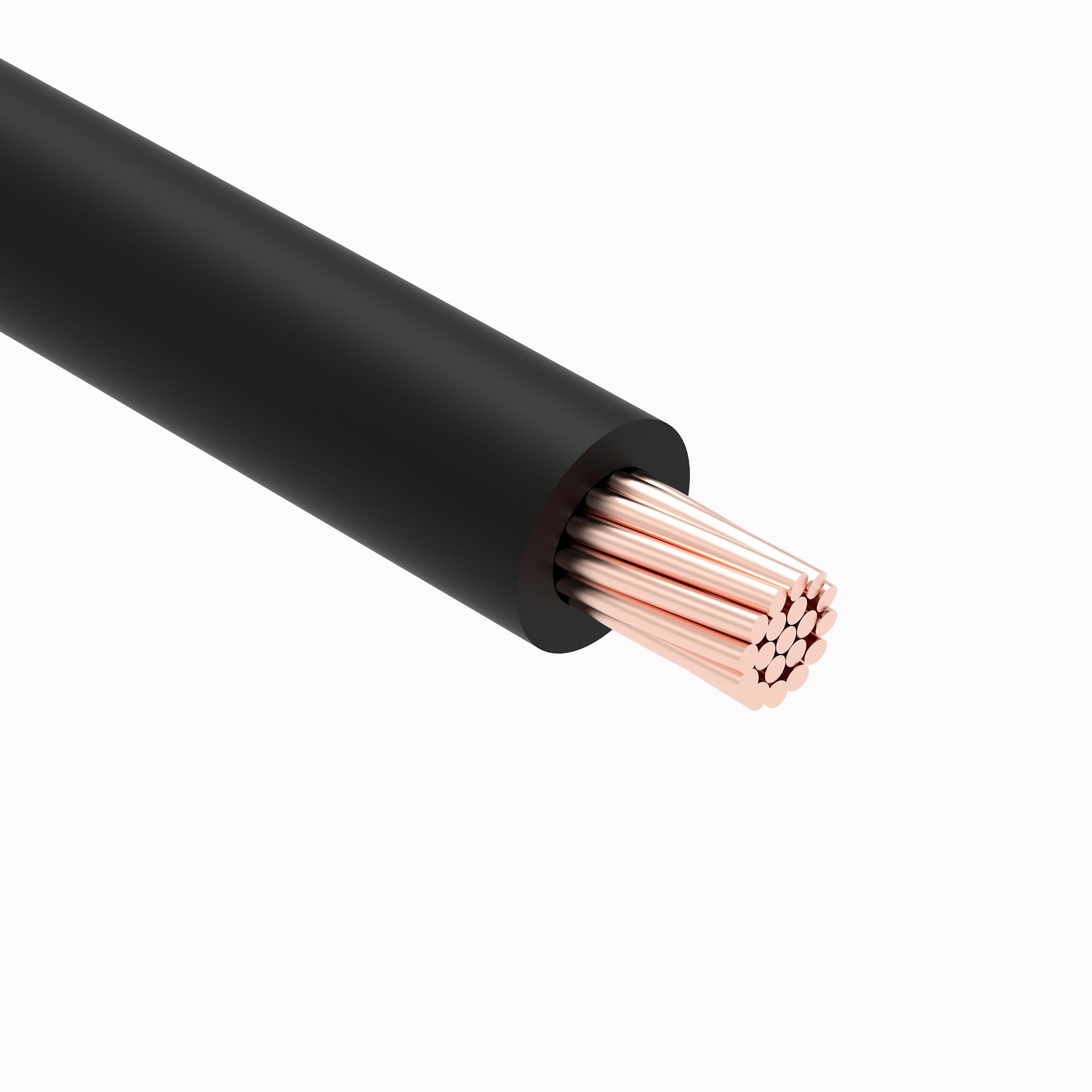

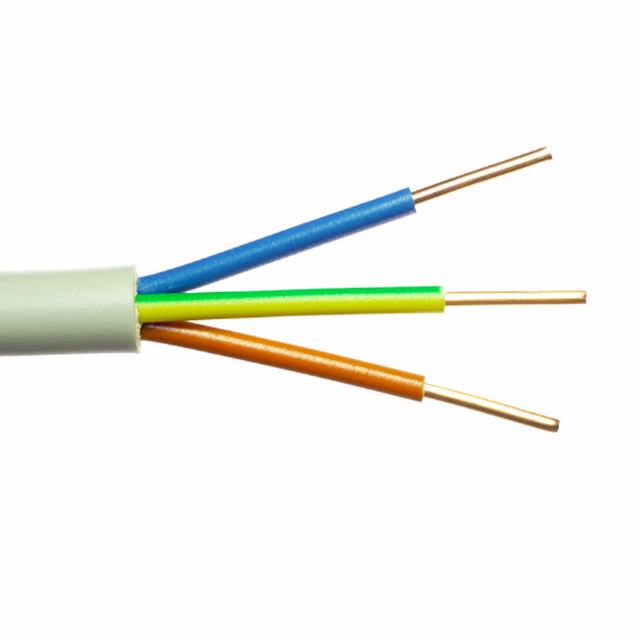

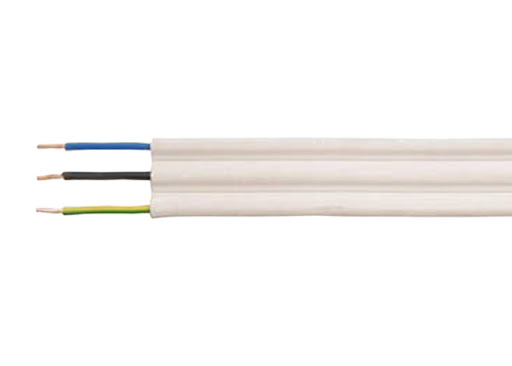

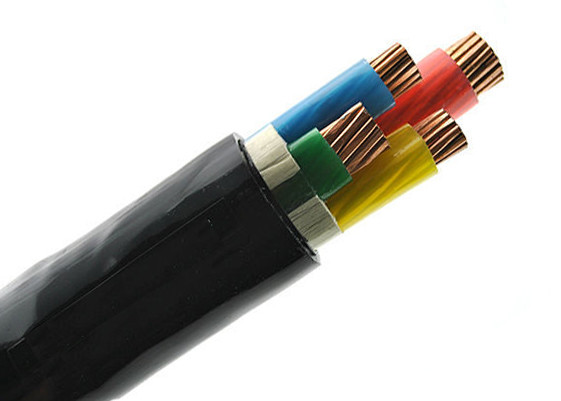

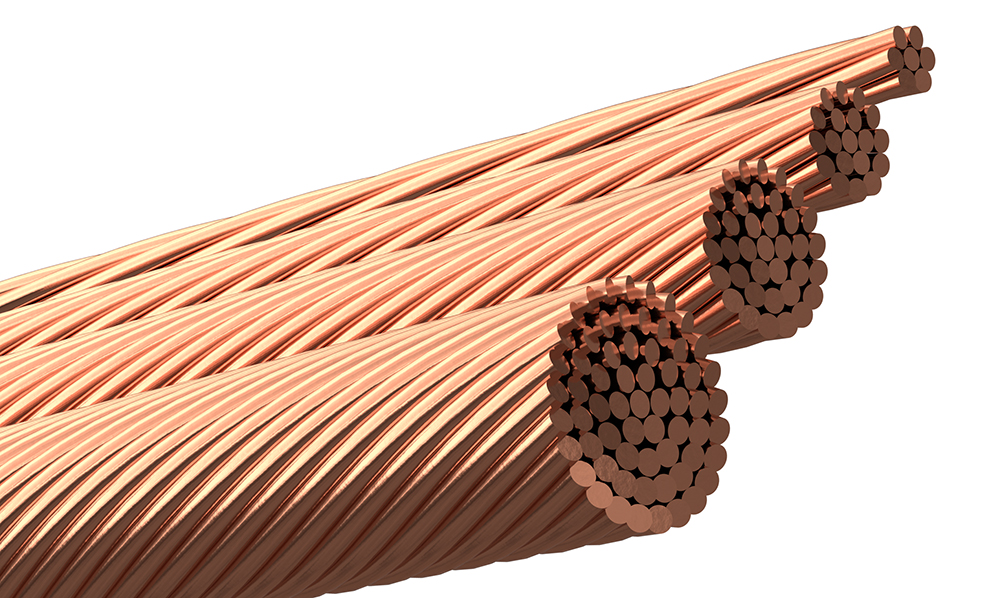

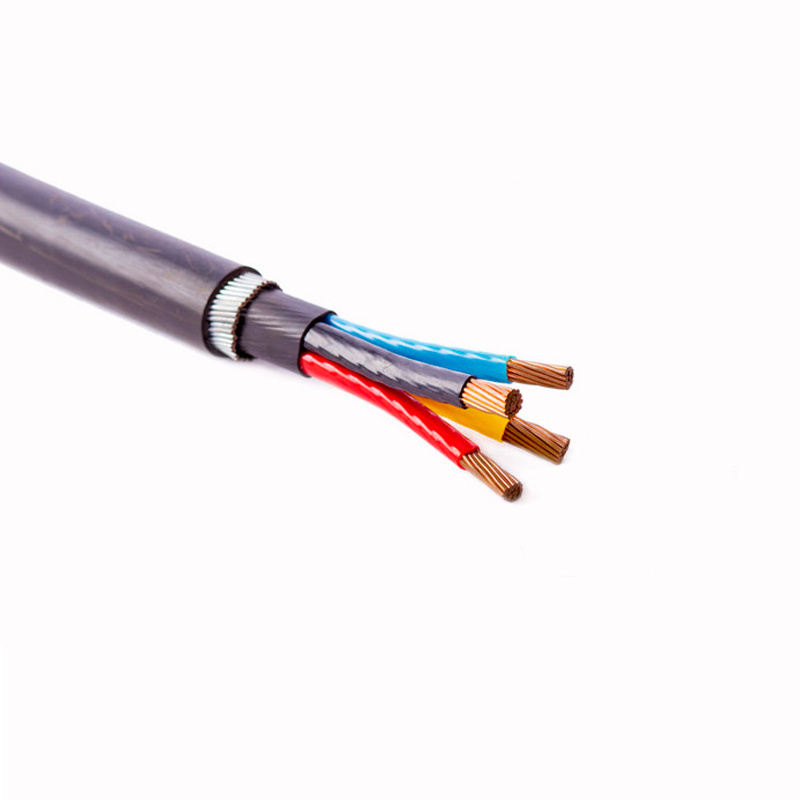

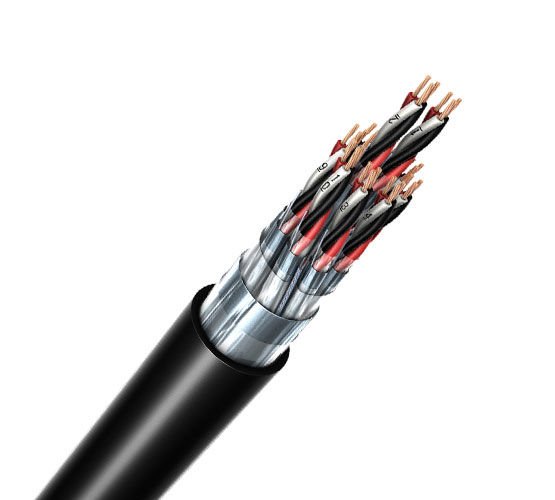

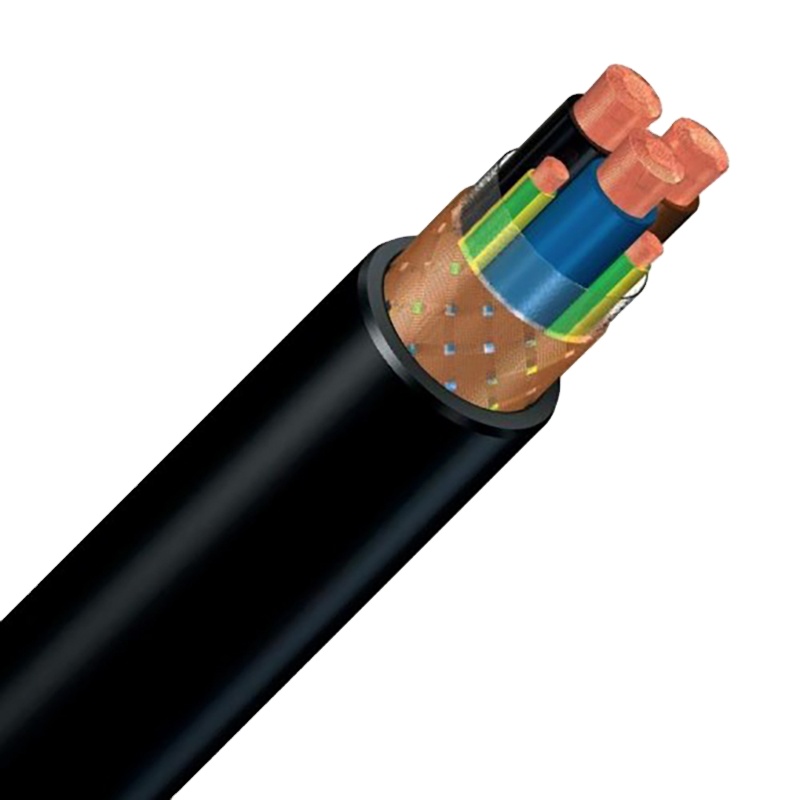

CONTROL CABLES Control Cables are the cables of choice for control circuits and instrumentation used primarily for providing data and voice communications services in industrial plants and specifically in the oil and gas production industry. At Riyadh Cables, we offer a range of Control Cables, with XLPE or PVC insulation, with the option of armour and/or screening. Our Control Cables are manufactured to IEC 60502-1 standards, and the conductors used in the manufacture of our Control Cables are Round Stranded Class 2 to IEC 60228. We can also provide Solid Conductors Class 1 as per IEC 60228, on special request. Special requests can also be accommodated for the outer sheathing of Control Cables. We are able to supply fire retardant PVC, anti-termite / anti-rodent PVC, sunlight resistant PVC, and oil resistant PVC. Special sheathing materials such as low smoke halogen free (LSHF), LLDPE, and MDPE are also available on request.