Stand:

Atlas India

Stand:

Atlas India

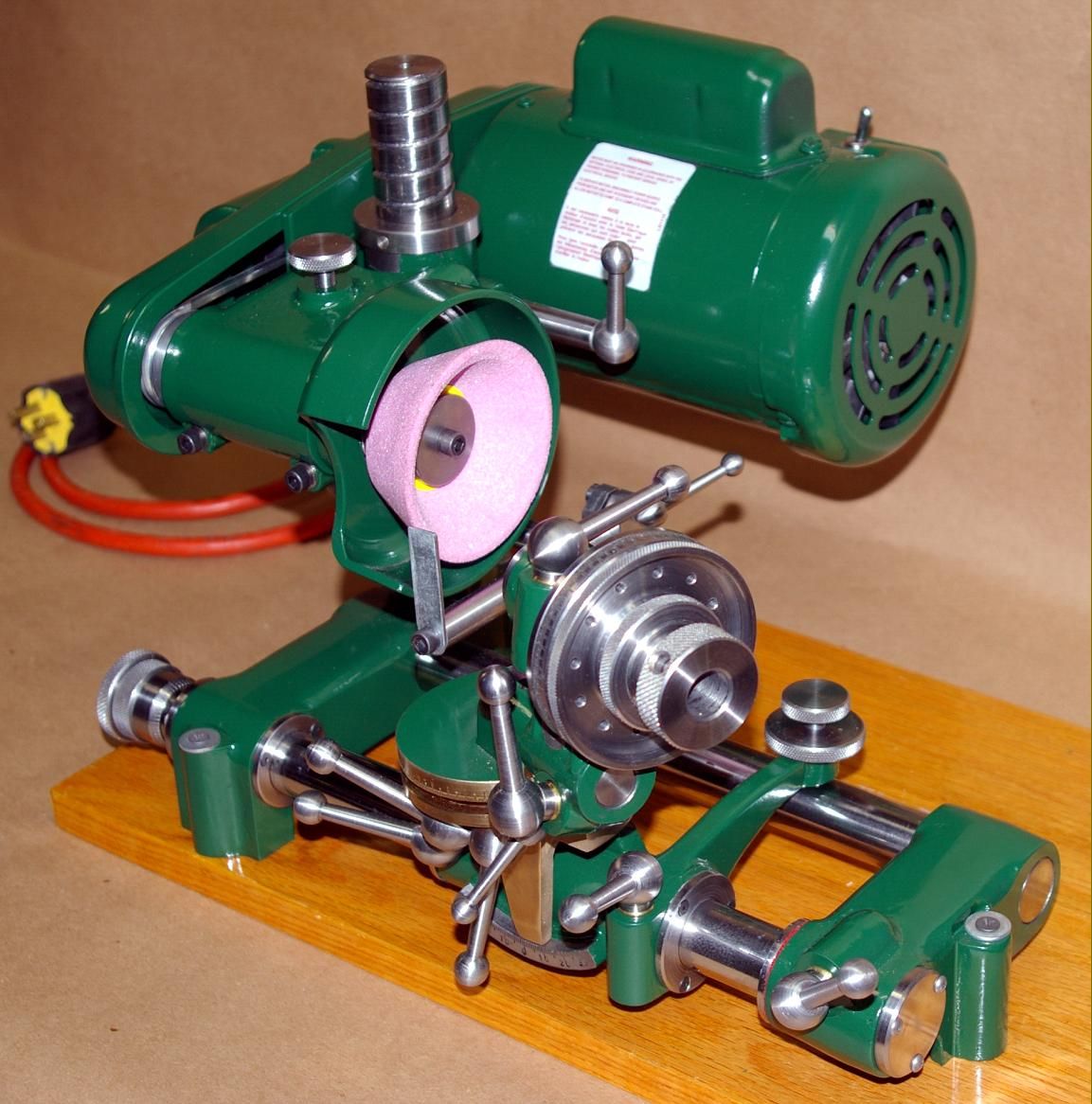

Tool & Cutter Grinder

Description

Special Features: The Universal Tool & Cutter Grinder is a robust machine capable of dealing with a wide range of tool & cutter Grinder operations. It is available as a steel cabinet mounted, machine and is designed for the rapid sharpening of H.S.S. milling cutters, spiral mills, metal slitting saws side and face cutters reamers, tap and with suitable attachments lathe tools, end mills formed cutters etc. A totally enclosed wheel head motor with a double ended spindle carriers one standard and one extended wheel adaptor which can be mounted on either end and will receive both the Cup and dish wheels supplied with the machine. The spindle, with runs at 2800 r.p.m. is controlled by reversing switch built into the main body of the machine. The wheel head is mounted on an engraved base plate which can swivel through 360D and can be clamped in any position. It is supported by a cast iron column having vertical adjustment, by means of a hand-wheel at the base of the machine. The column can be looked in any position and movement can be accurately controlled by means of a friction mounted micrometer dial. The upper work table is provided with the slot which not only serves as means of fixing the tooth rest etc. but also enables accurate location of the loose centre heads. It is graduated either side of the Zero setting and can swivel through 180D Provision is also made for taper setting in INCHES per FOOT. Longitudinal movement of the table is obtained from a rack pinion operated by a conveniently placed Handle or, if required, can be operated by hand pressure only. The table is located on accurately machined vee and flat ways and is fitted with adjustable stops which can limit he movement of the table in and position. Cross traverse is accurately controlled by a hand wheel situated at the front of the machine which is fitted with a friction mounted micrometer dial. STANDARD EQUIPMENT TOOL KITTool & Cutter Grinder