Assiut Portland cement – CEM I (32.5 N)

Portland cement was the first cement to be produced all over the world, and the most popular one. It was named “Portland” because of the similarity in shape and color with the cement material and limestone, which exists in Portland Island, in England. It is defined as the hydraulic bonding grey fine powder, which is the result from crushing a dry mix, made of clinker and gypsum. Adding and mixing water to it hardens this grey fine powder, which is known as the initial setting, and this is what makes it resistant to water and able to bare compressive stresses.

Uses and applications

It can be used in all concrete construction such as reinforced buildings, water tanks, roads, and any other building works, which are not subjected to sulphate effect.

It also can be used in relevant industries of the construction, as hollow and solid blocks, tiles and railway line concrete supports.

Standard specifications: CEM I (32.5N)

- Egyptian Standard Specifications (ES. 4756-1 / 2009)

- European Standard Specifications (EN 1-197 /2004)

- American Standard Specifications (ASTM C150/2007 Type I)

Chemical properties

|

|

Average Results

|

Egyptian Specifications(4756-1/2007)

|

|

Mgo

|

1.2 – 1.6

|

|

|

SO3

|

2.5% - 3.0%

|

Not more than 3.5%

|

|

Loss of ignition

|

2.0 % - 3.0%

|

Not more than 5%

|

|

Insoluble residues

|

0.4% - 0.7 %

|

Not more than 5%

|

|

Chlorides Contents

|

0.02 - 0.04

|

Not more than 0.10%

|

|

Clinker Contents

|

|

|

|

C3S

|

50 - 55%

|

|

|

C2S

|

20 - 25%

|

|

|

C3A

|

6.0 - 7.0%

|

|

|

C4AF

|

11 - 13%

|

|

|

Lime Saturation Factor

|

0.92 - 0.94

|

|

Physical and Mechanical properties

|

|

Average Results

|

Egyptian Specifications(4756-1/2009)

|

|

Surface area cm2/gm (Blaine Method)

|

3100 - 3300

|

N.R.

|

|

Setting time Initial setting time

|

130 - 170

|

Not less than 75 min.

|

|

Soundness (Le Chatellee )

|

0 - 1

|

Not more than 10 mm

|

|

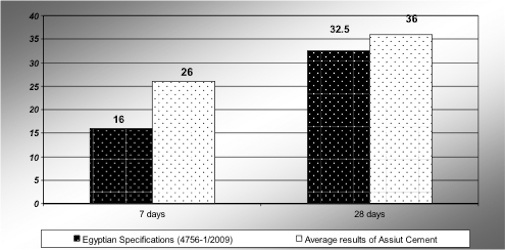

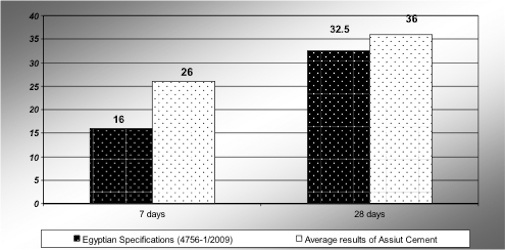

Compression Strength N/mm2

|

|

|

|

After 2 days

|

15-19

|

N.R.

|

|

After 7 days

|

24-27

|

Not less than 16 N/mm2

|

|

After 28 days

|

34-38

|

Not less than 32.5 N/mm2

|

Packing

- Bags: 50 Kg/bag.

- Jumbo plastic bags: 500 Kg/bag, 1000 Kg/bag, 1500 Kg/bag.

- It is also available in bulk.

Storage

It is recommended to follow the coming instructions:

- Storage should be done in a dry place and away from ground moisture.

- It is preferable to store it on wooden bases.

- Cement should be covered to avoid the rain.

- It is recommended not to pile up any more than ten bags, some on others.

Shelf time

It is recommended to retest the cement after 6 weeks since the production date.

Safety recommendations

It is recommended to follow the coming instructions:

- Avoid the contact of the cement with the eyes and the skin since it may cause allergic reaction.

- Use gloves and glasses to protect hands and eyes in case of spray applications, or manual mixings.

How to clean the cement remains of the used tools

- Before setting: by using clean water.

- After setting: by using mechanical methods.

Environment concept

It is advised and recommended to follow local environmental instructions..

Stand:

Cemex

Stand:

Cemex