Stand:

WIKA

Stand:

WIKA

Ultra-high purity transducer - For explosion-protected areas

Description

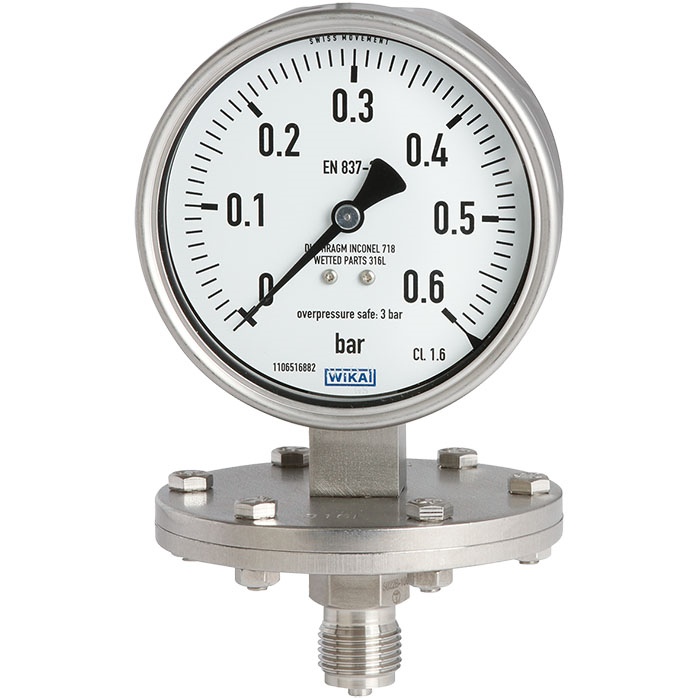

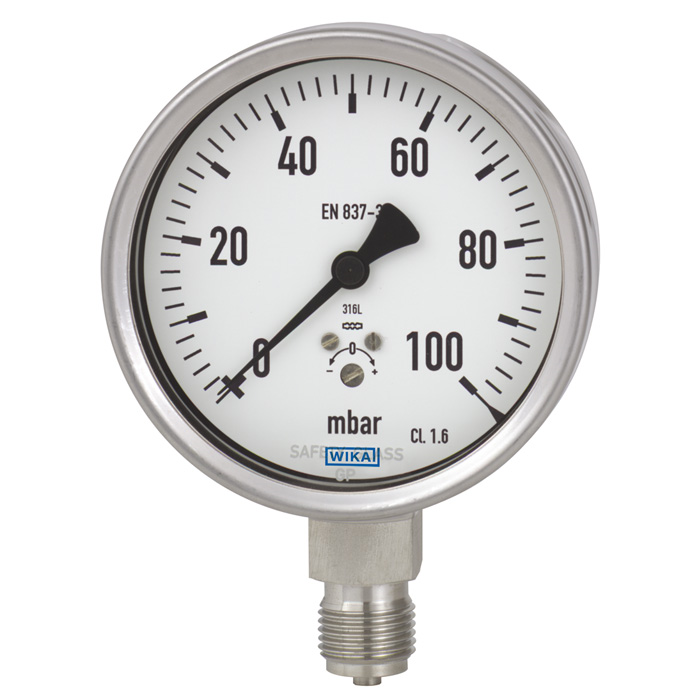

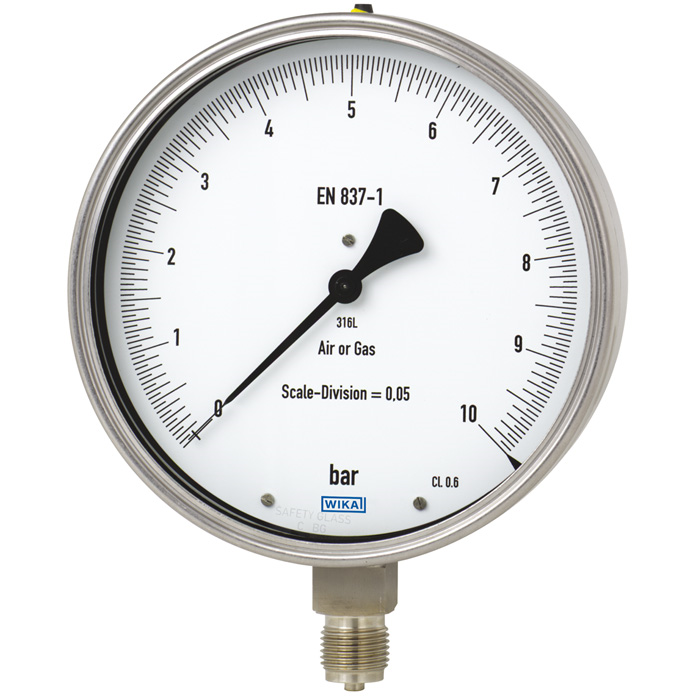

Models WUC-10, WUC-15, WUC-16 Applications Compact The WUC-15 and 16 series transducers are notable for their excellent self-draining characteristics. The special sensor connection design eliminates the influence on the sensor signal through loads on the process connections or weld seams. Versatile This series of instruments was also developed for use in Ex zone 2. The T6 temperature class classification ensures that even measurements of media with low self-ignition temperatures, such as PH3 (phosphine), do not present a problem. Reliable Through the sealed “side access” zero point adjustment, the high IP67 ingress protection is permanently maintained. Simple handling and protection from unintentional adjustment are ensured. For all wetted parts, the materials 316L VIM VAR and special thin-film sensors from 2.4711 / UNS R30003 are used. Before final assembly, all wetted parts are electropolished and cleaned using state-of-the-art processes. Through an individual examination of each transducer, it is ensured that the required values for leak tightness, overpressure stability, accuracy, and particles are met by the applicable SEMI™ standards.Ultra-high purity transducer - For explosion-protected areas

Special Features

Description

The space-saving design of the model WUC-1x provides greater free space in plants and installations.

The high IP67 ingress protection also enables them to be used under harsh conditions on tank farms and specialty gas installations outdoors.

With cyclic pressure rinsing, high gas throttling values (Joule-Thompson effect), and external operation, high-temperature fluctuations can occur. The active temperature compensation detects these changes and minimizes their influence. Thus stable measurement is ensured.