Stand:

Bahra Electric

Stand:

Bahra Electric

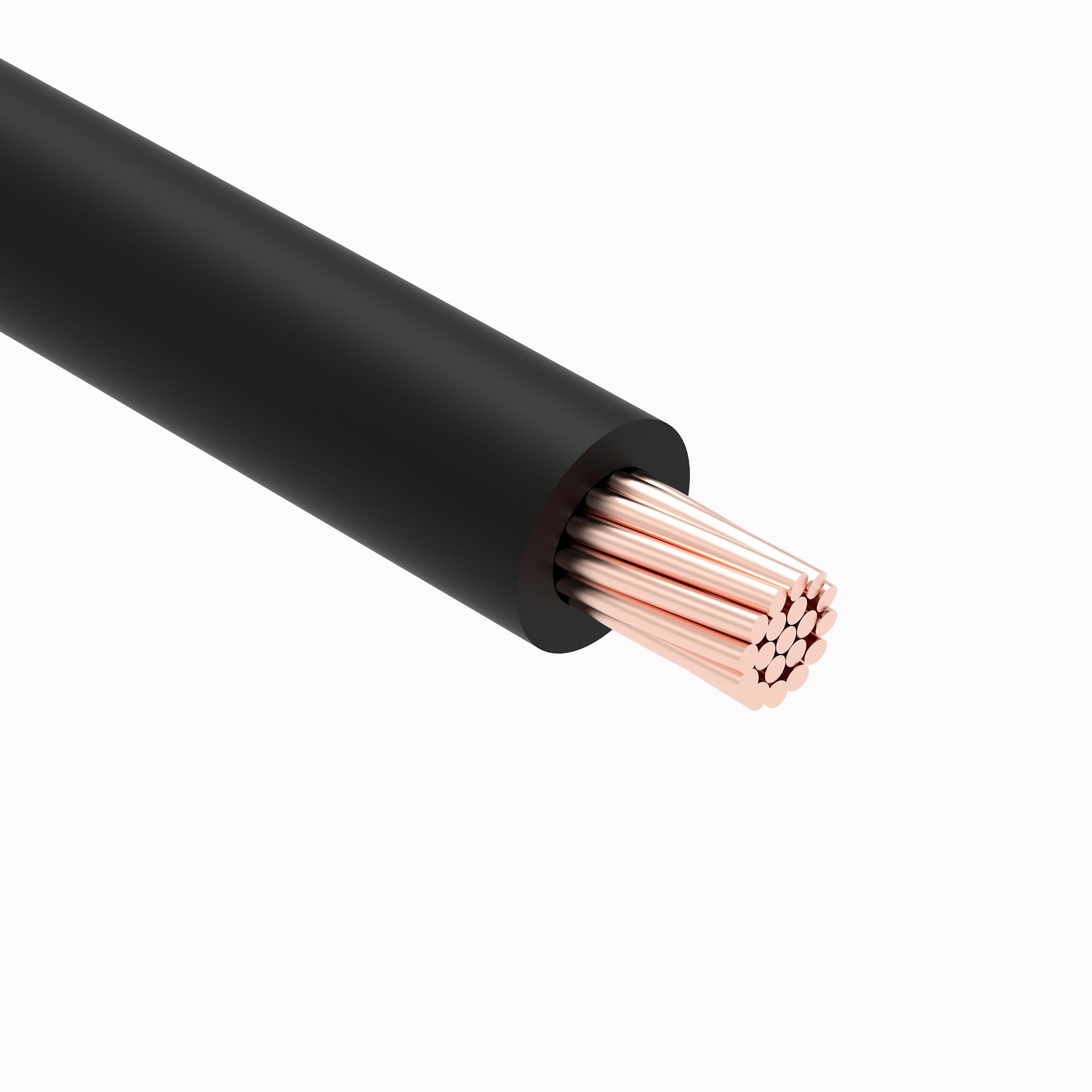

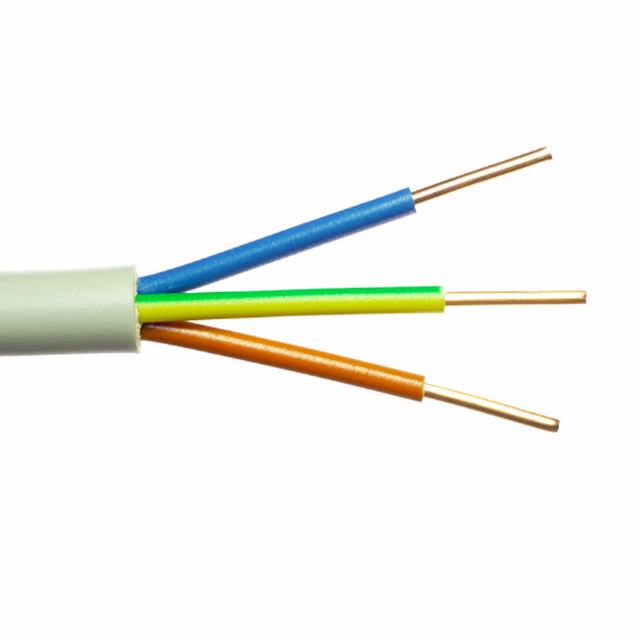

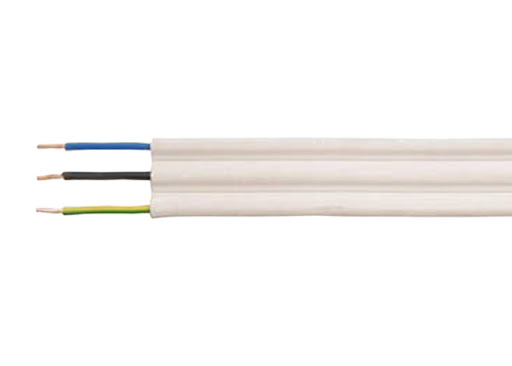

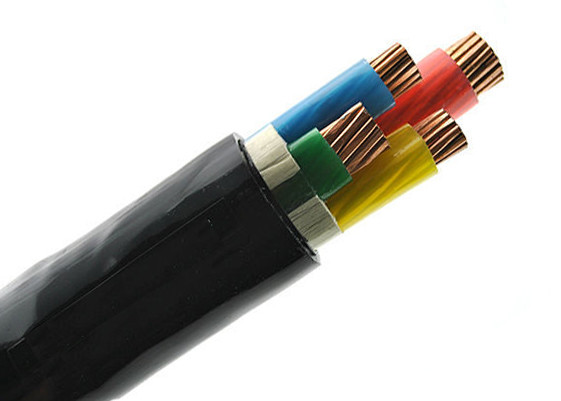

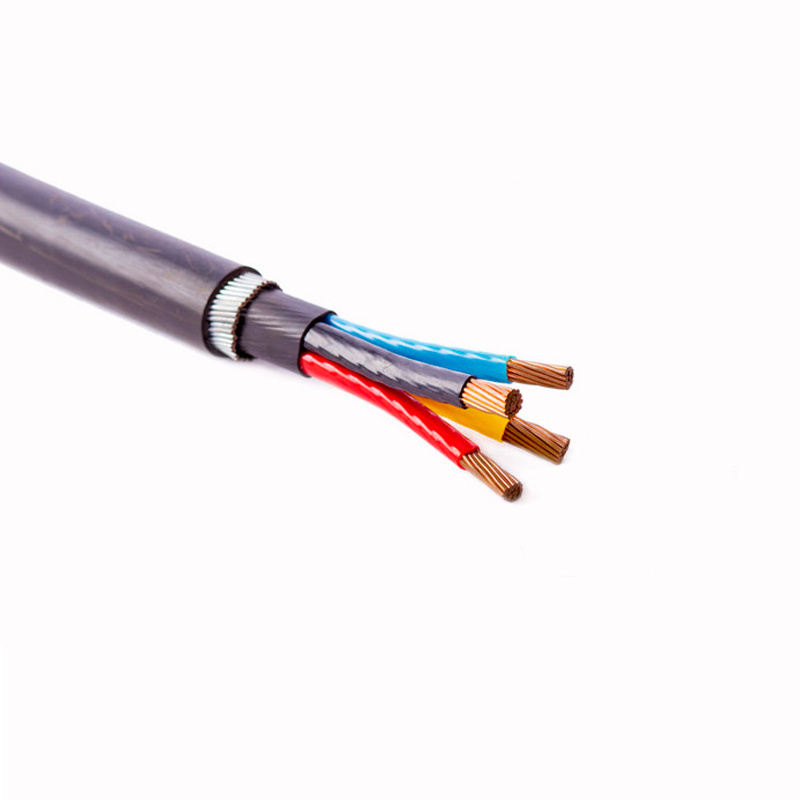

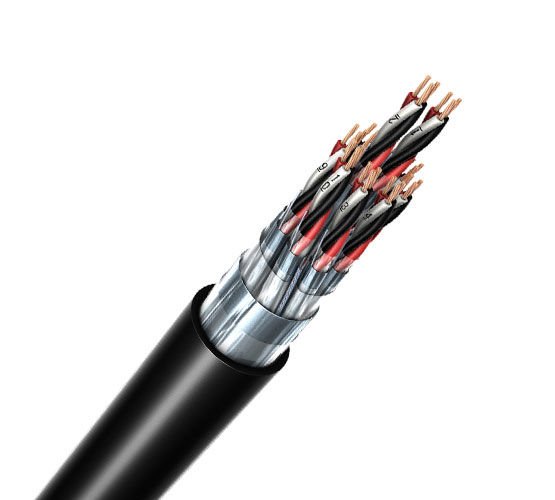

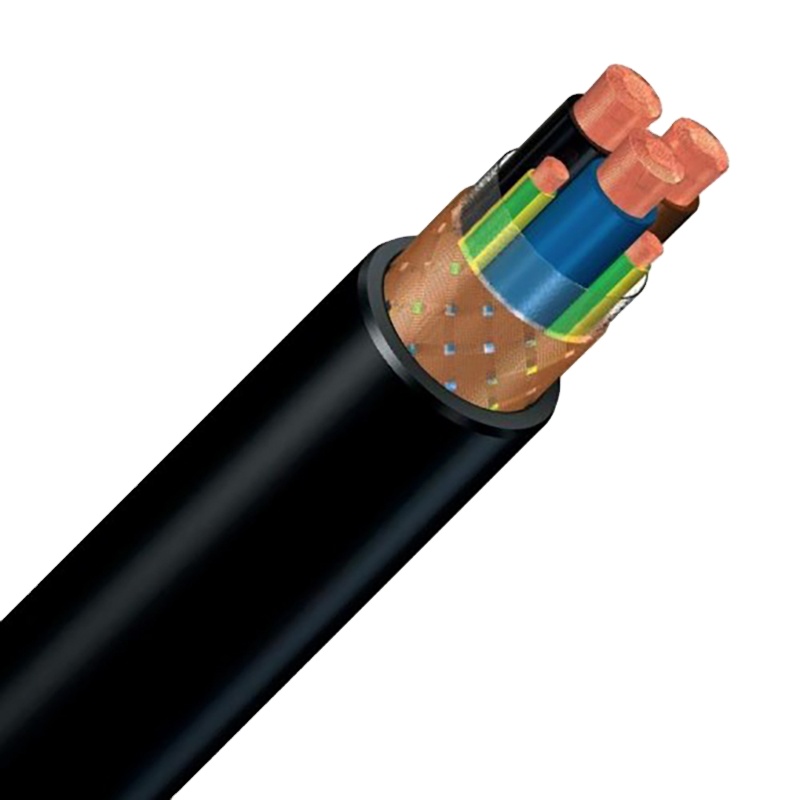

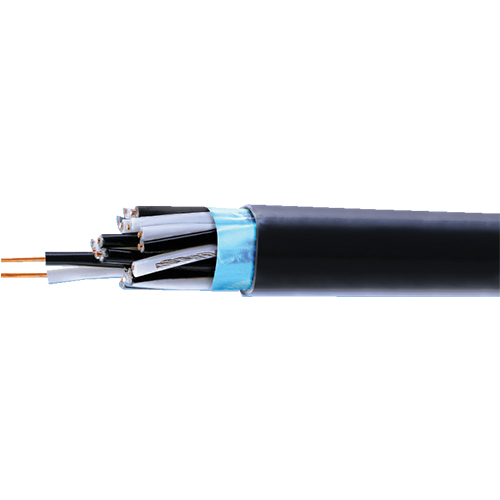

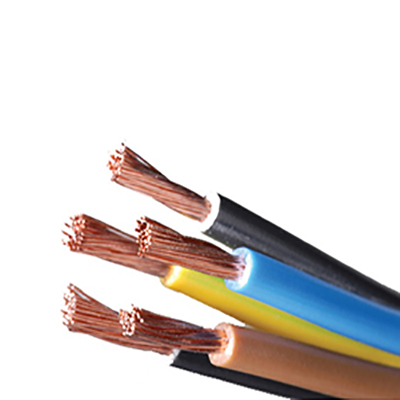

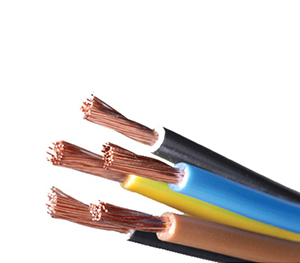

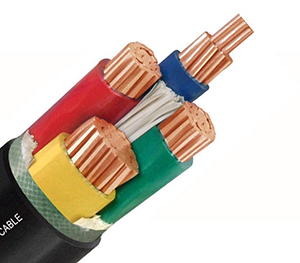

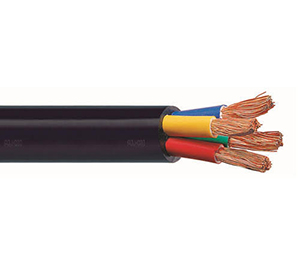

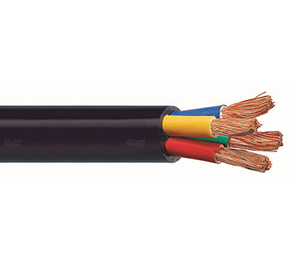

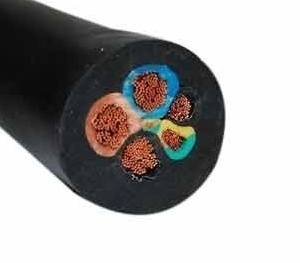

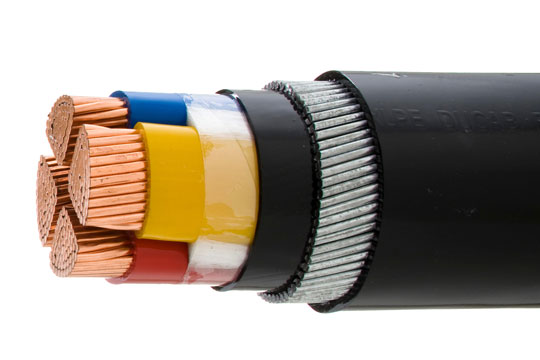

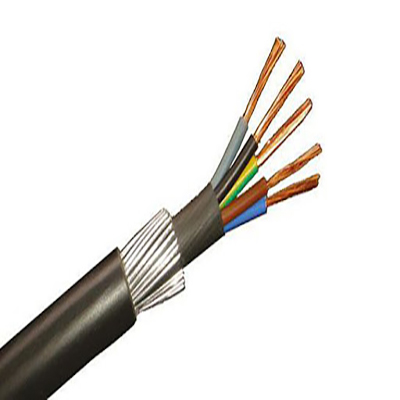

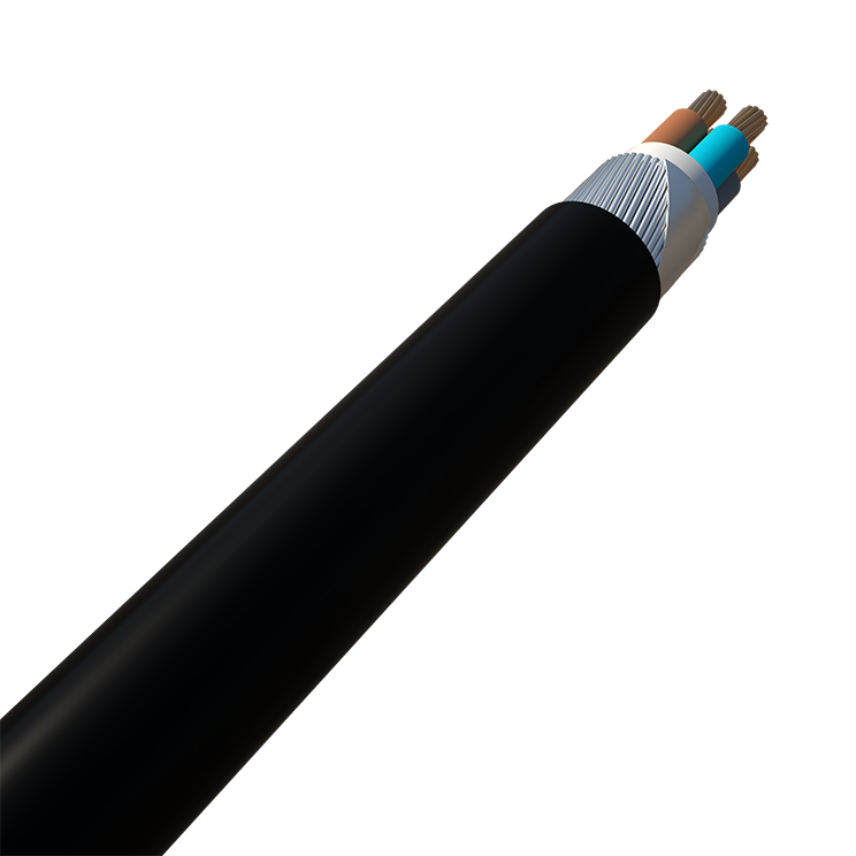

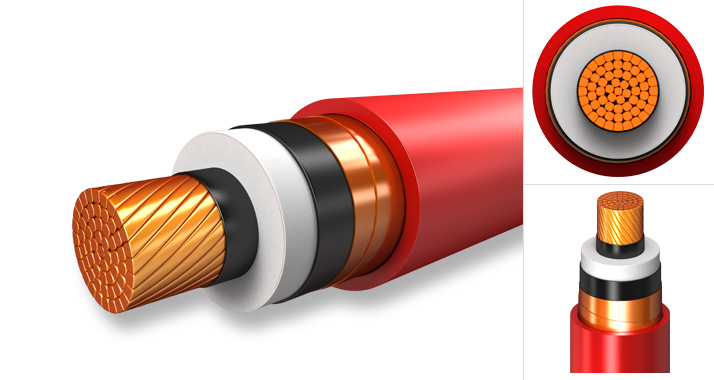

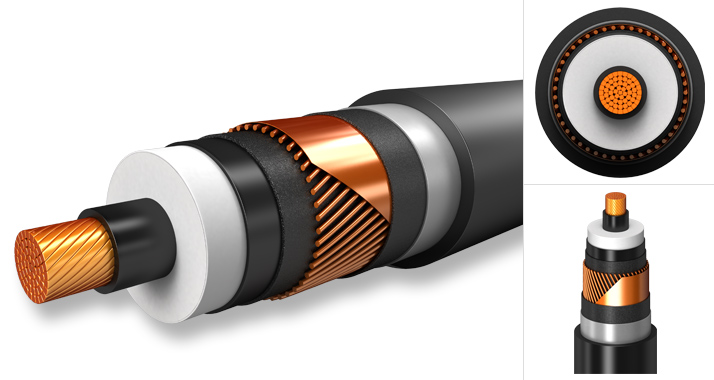

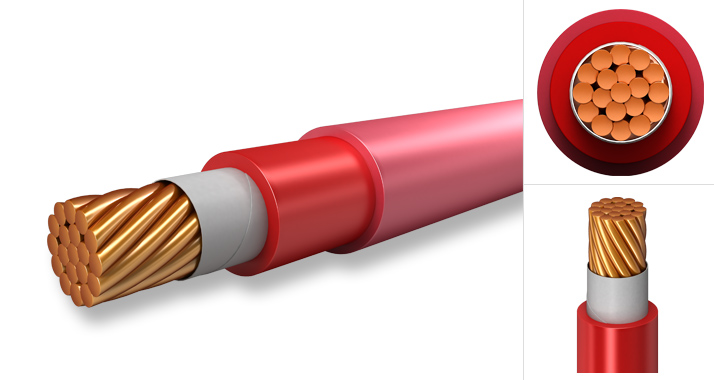

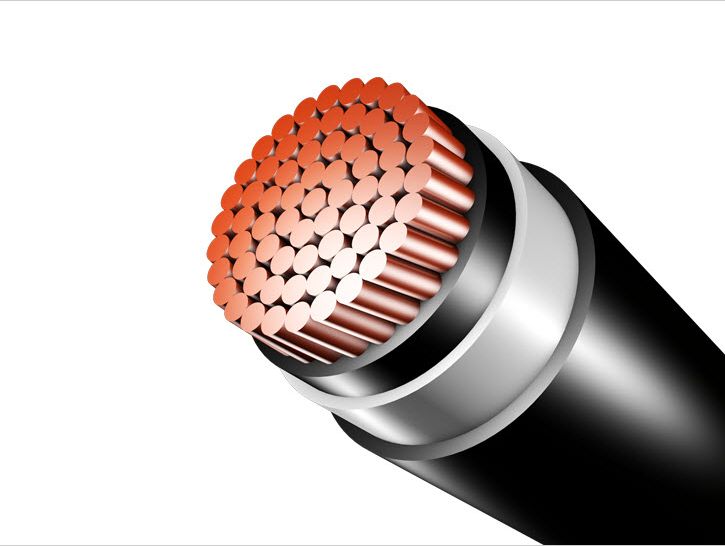

Medium Voltage Single and Multi-core XLPE Cables, up to 36kV

Description

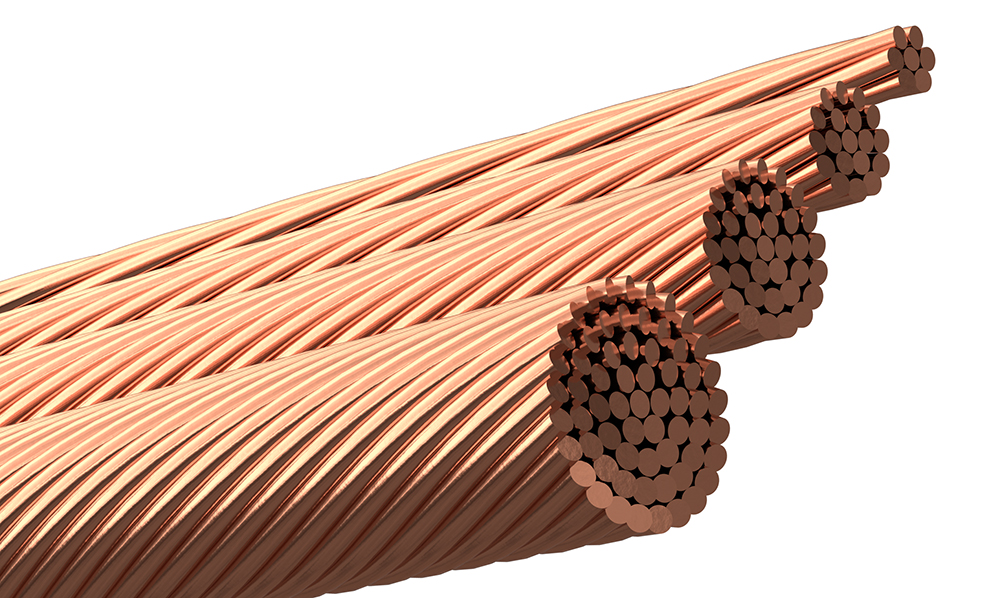

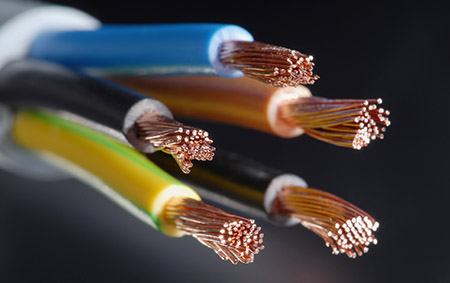

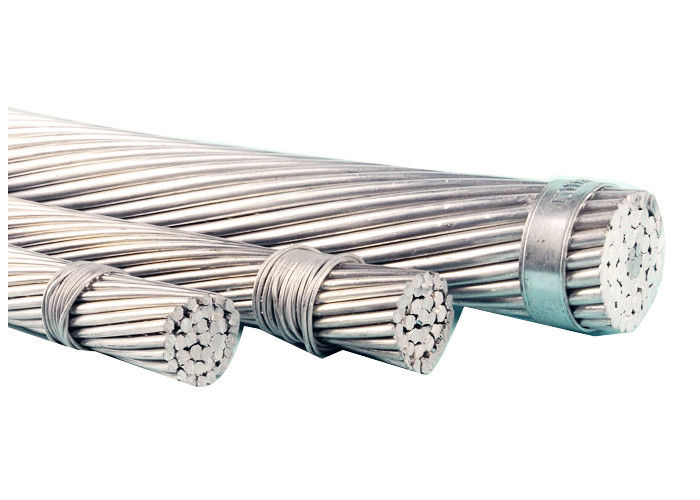

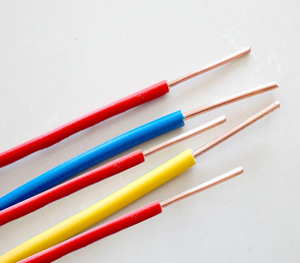

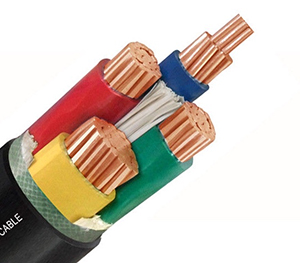

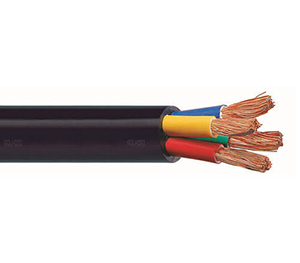

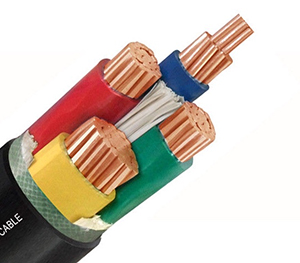

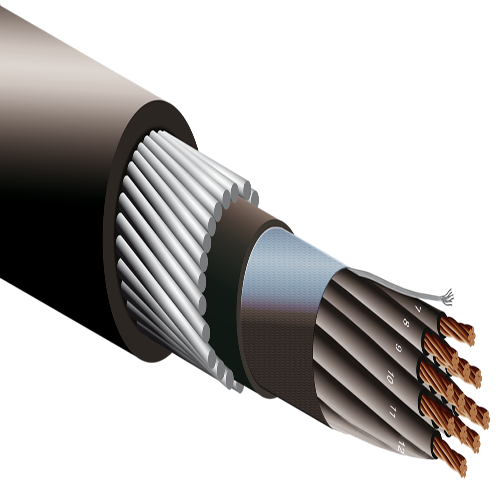

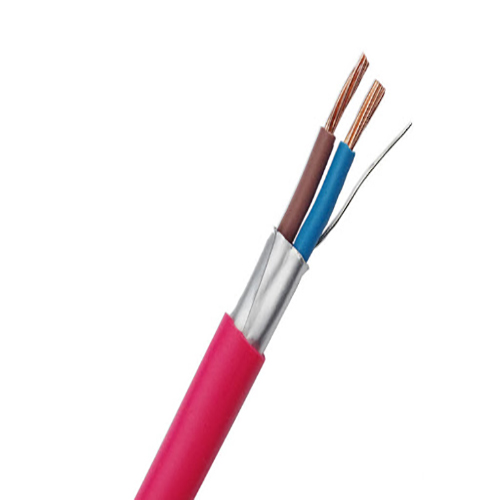

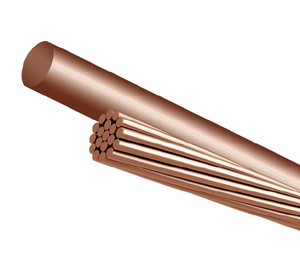

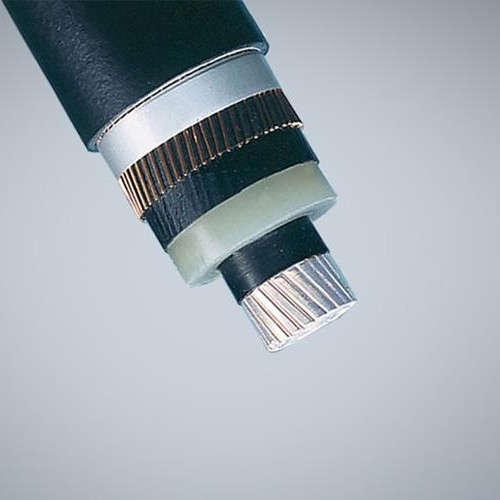

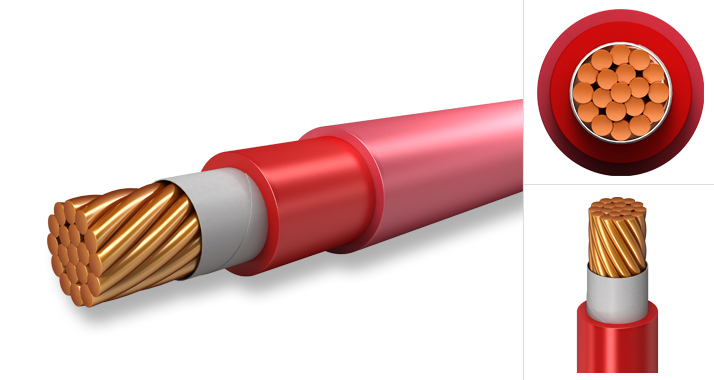

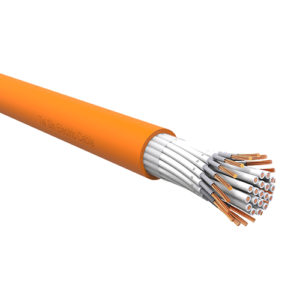

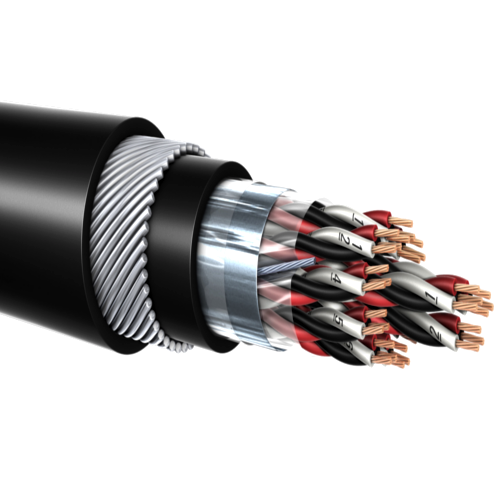

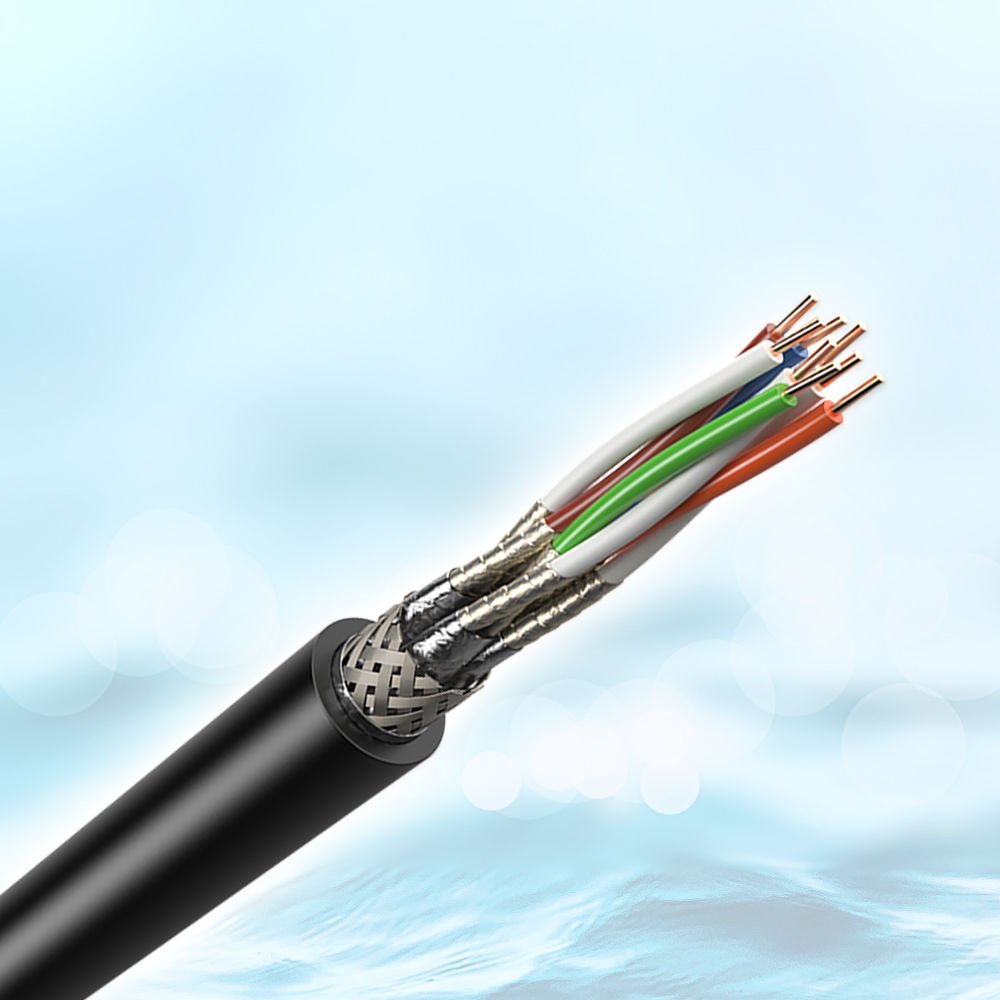

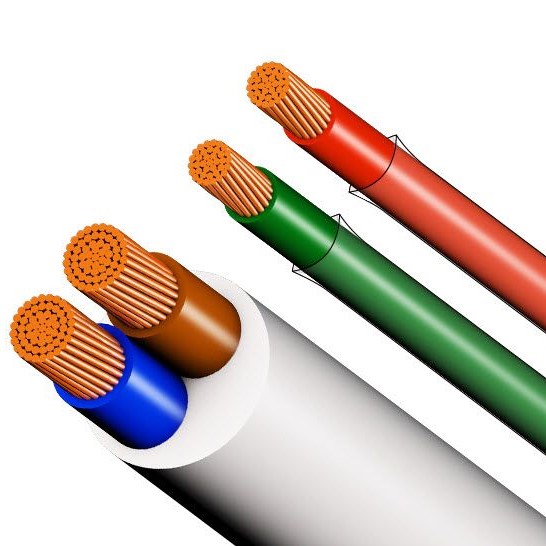

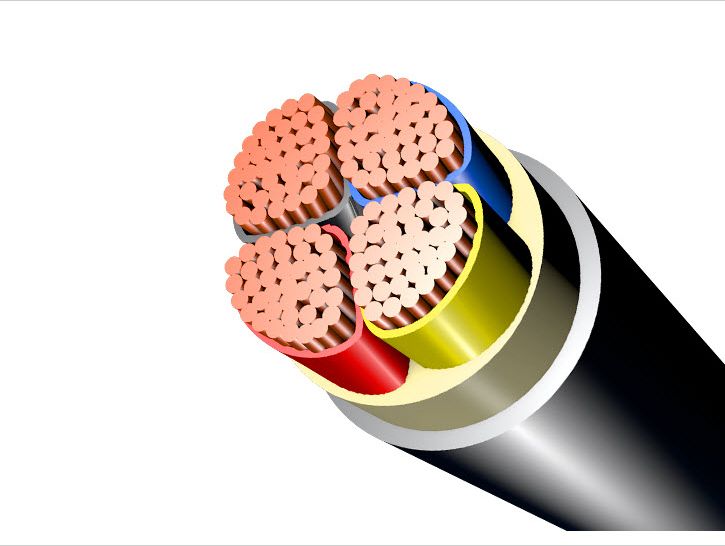

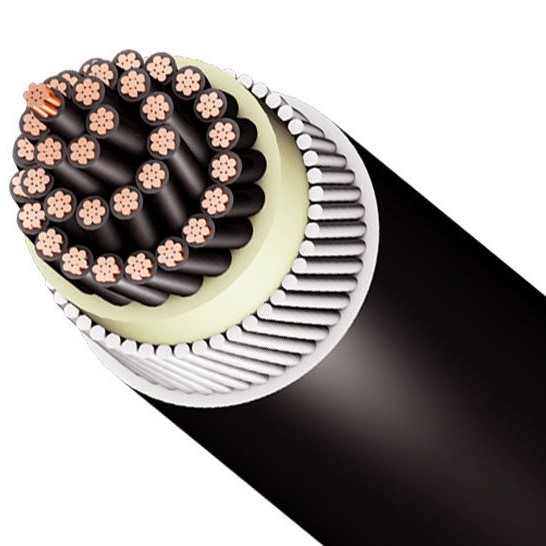

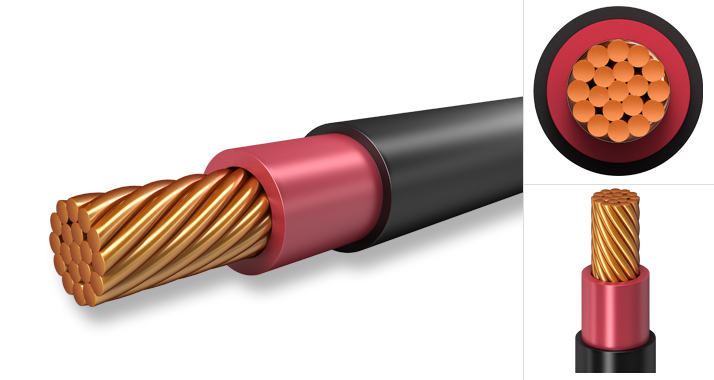

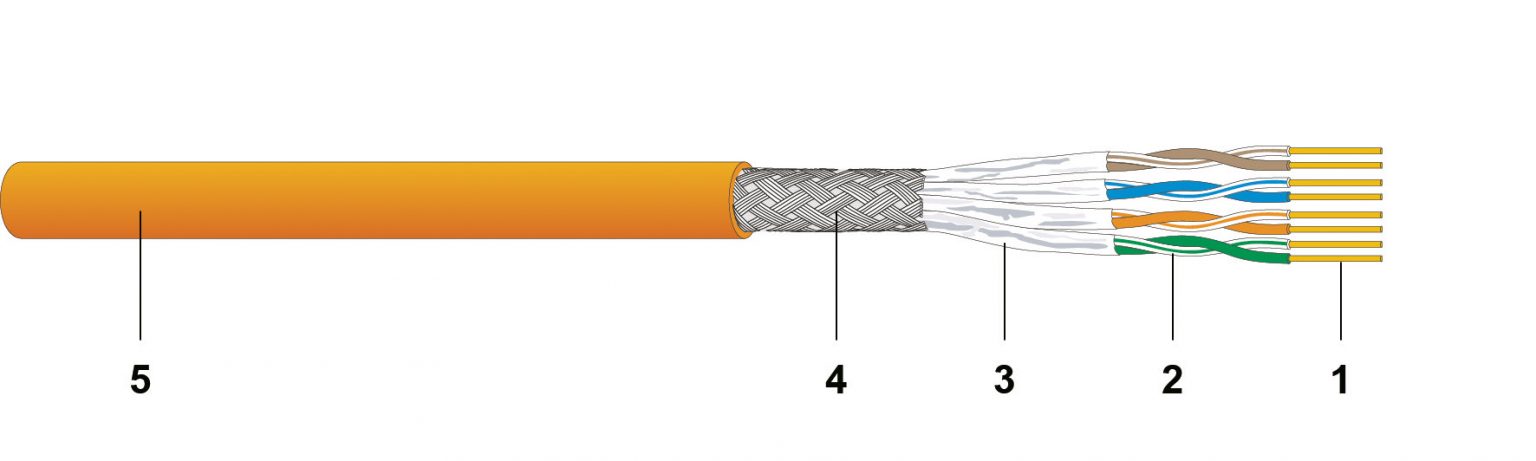

BE has the production lines with state-of-the-art Catenary Continuous Vulcanization (CCV) technology with the advanced automatic concentricity control system, which guarantees high-quality+03 products to comply with International (IEC) and British (BS) standards. BE carries out routine, sample, and type tests (electrical/mechanical) in its laboratories accredited by A2LA ISO/IEC 17025:2005. BE products are also tested internationally with reputable labs such as KEMA, KSU, BASEC, and are global. BE is included in the supplier's list of many utilities in KSA, GCC, and other countries like ARAMCO, SEC, SEWA, ADWEA, MARAFIQ. Specification: Electrical medium voltage power cables comply with IEC 60502-2, BS 6622, and BS 7835. All cables are Flame Retardant to IEC 60332-1 Vertical Flame Propagation Test. Conductor: High conductivity soft annealed copper conductor and aluminum conductor according to BS EN 60228, Class 2 stranded round compacted. Insulation: Cross-linked polyethylene (XLPE) or tree-retardant cross-linked polyethylene (TR-XLPE)with a maximum service temperature of 90ºC. Metallic Screen: Copper wire screen - cross-section upon request or short circuit current Copper tape screen Armoring (upon request): Galvanized steel wire “SWA” or galvanized double steel tape “STA" for multi-core cable Aluminum Wire Armored “AWA” or Aluminum Tape Armored ATA for single core cable Outer Sheathing: PVC ST2, LS0H ST8, LDPE, LLDPE, MDPE and HDPE ST7 Special Requirements (upon request):Medium Voltage Single and Multi-core XLPE Cables, up to 36kV

MV Power Cables are produced for projects in power generation, and electricity transmission and distribution.