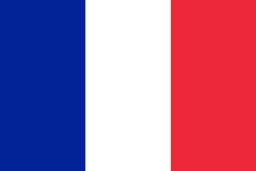

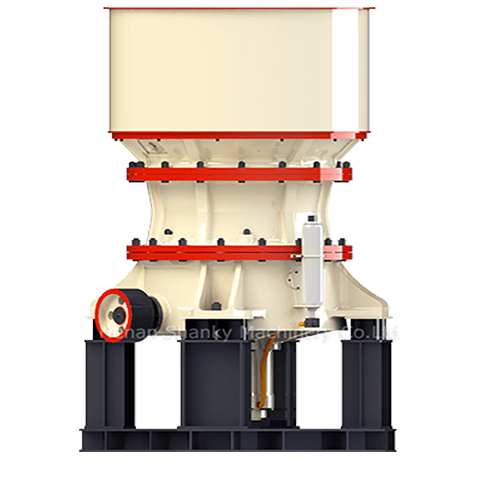

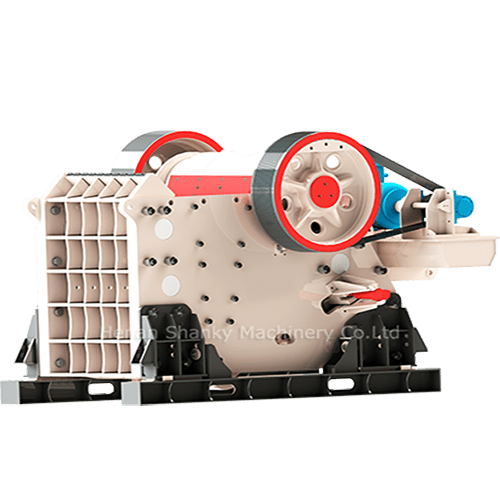

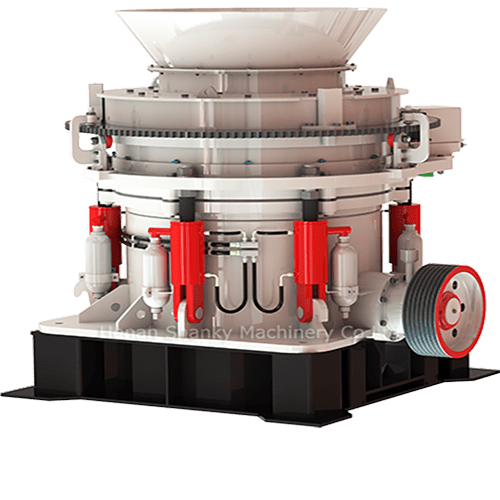

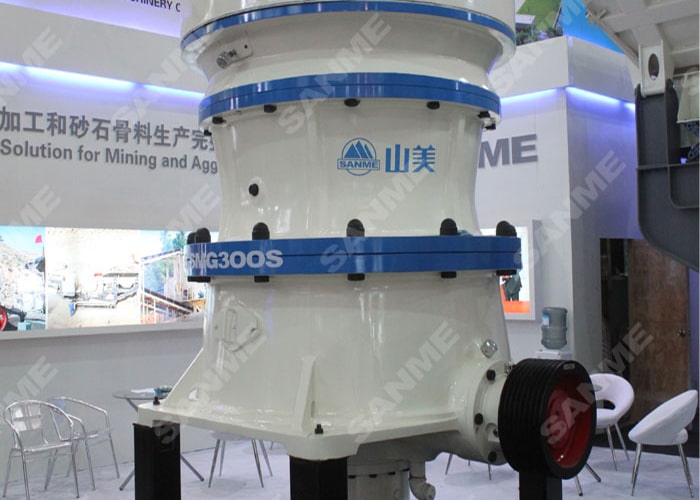

GP Series Cone Crusher

Description

widely used in quarry, mining, coal mining, concrete mixing station, dry mortar, power plant, and so on. Applications: river stone, granite, basalt, iron ore, quartz, diabase, iron ore, gold ore, copper ore, etc 60-560Max.feeding Size(mm)75-630Power(kW) Product Brief Introduction Lubrication and hydraulic integration, low production cost. The integrated design of the hydraulic pressure station and lubricating station saves installation space. Optimized components layout and tank volume can make operation and maintenance simple and decrease operating costs. Optimized designed structure brings long service life Sliding bearing adopts a special oil wedge design, which can avoid direct frictional contact between the shaft and bearing. Reinforced frame structures and special bearing materials have large carrying capacities and high reliability, which can extend the service life of this equipment. Laminating crushing; Good product shapes and large production capacity The machine adopts the principle of laminating crushing, which improves the product shape to be cubic. The reasonable coordination of eccentricity, cavity shape, and parameters greatly improves the production capacity and efficiency of the equipment. Integration of discharge port adjustment and overload protection;Reliable performance. GP series single-cylinder hydraulic cone crusher integrates discharge opening adjustment and overload protection functions as a whole, which simplifies the structure and enhances reliability. All different sizes have different cavity types to meet different crushing requirements. All maintenances are processed from the upper part, which makes maintenance more convenient. The best cavity design and adjustable stroke GP series cone crushers can be easily adjusted for different production requirements. With a wide selection of cavities, the same crusher can be used in 2nd, the 3rd, or 4th crushing stages, producing different end product sizes, and meeting the different demands of customers. The stroke change feature allows the crusher through-put to be easily adjusted to work in harmony with the rest of the crushing plant. The adjustable stroke also allows you to attain proper choke feed conditions and optimum crusher settings, ensuring the maximum yield of a required end product size. Technical ParametersGP Series Cone Crusher

GP Series Cone Crusher