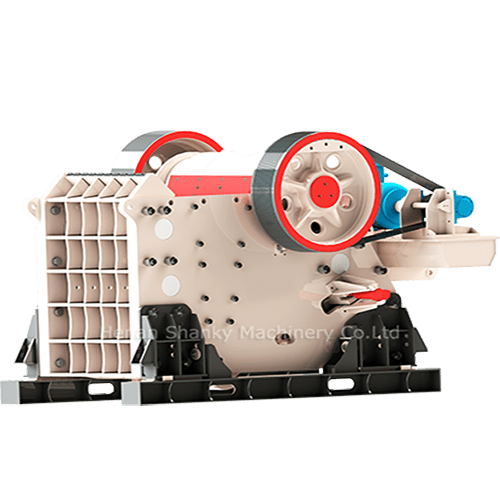

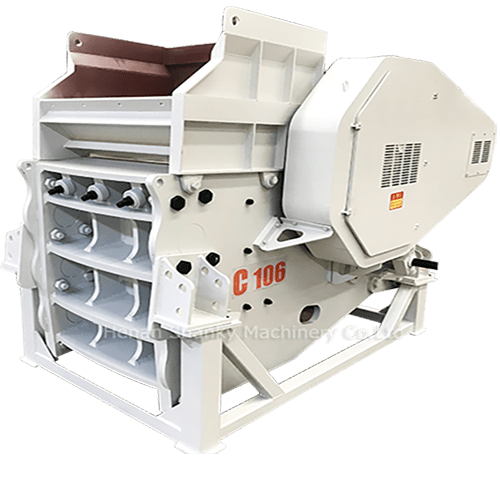

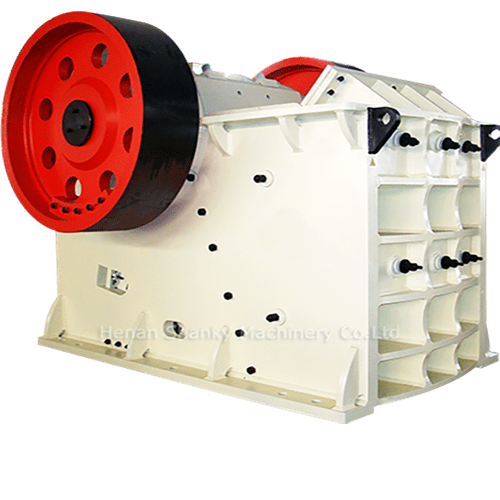

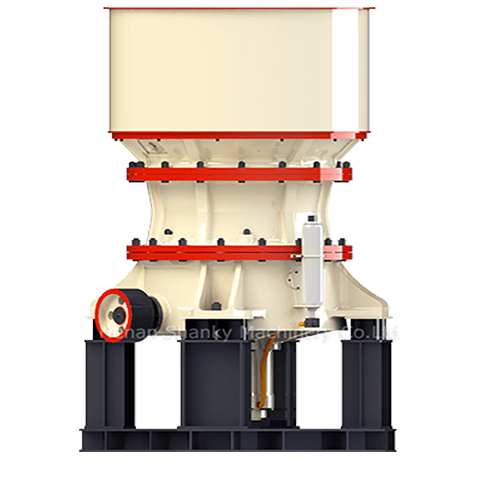

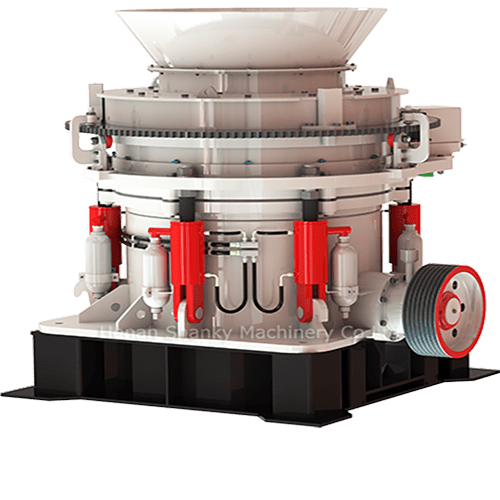

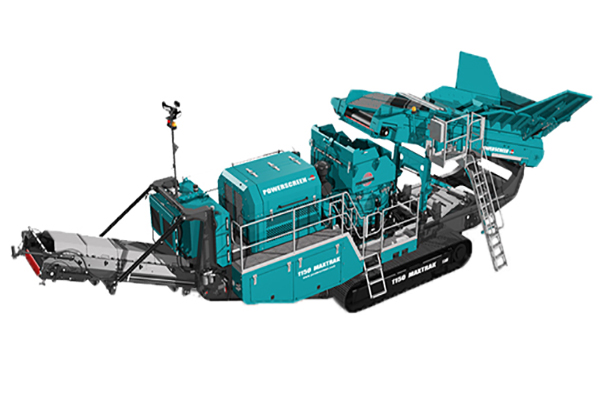

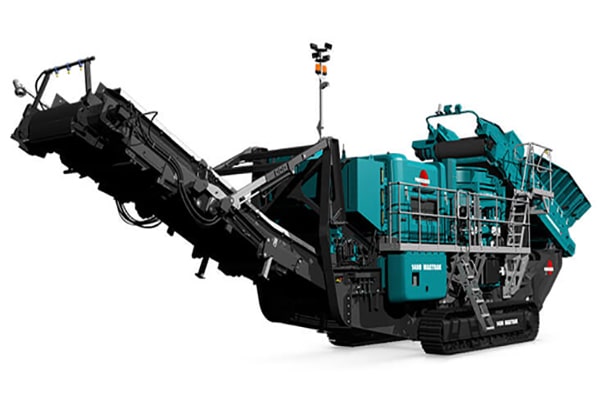

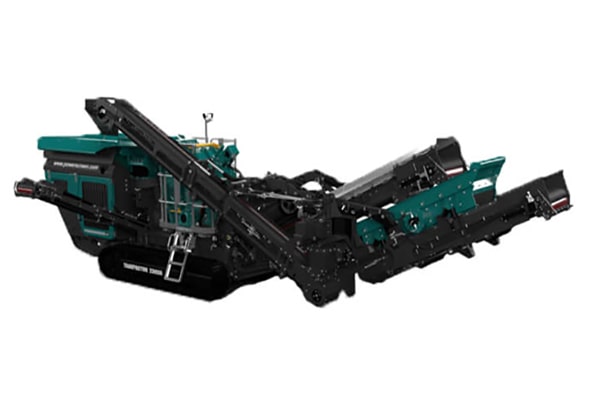

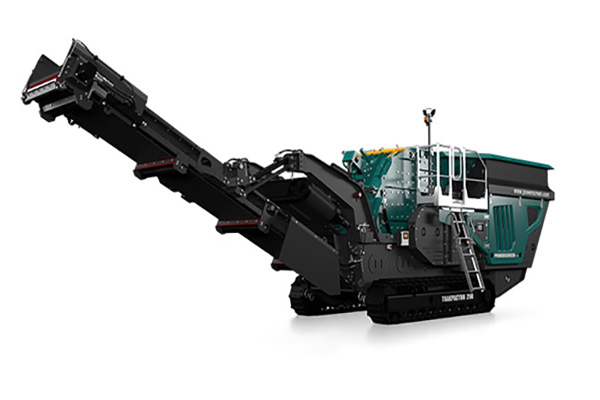

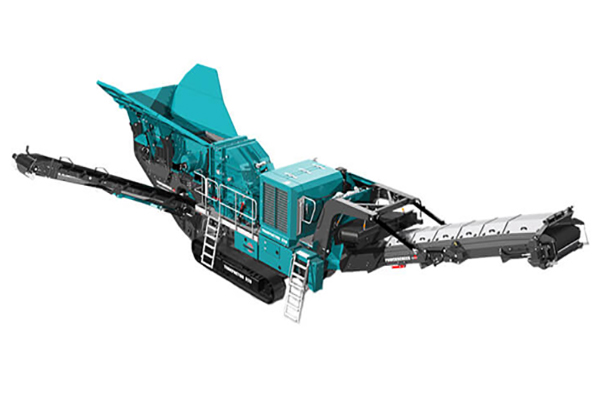

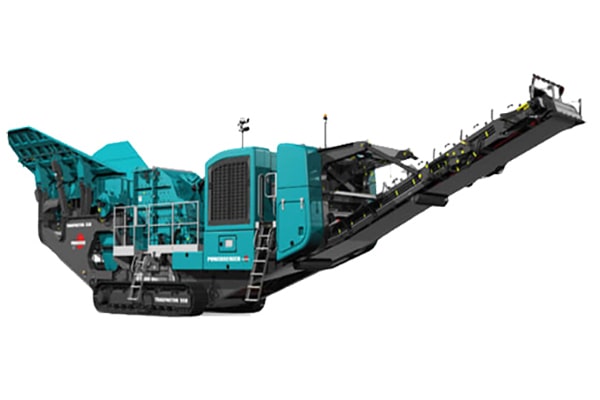

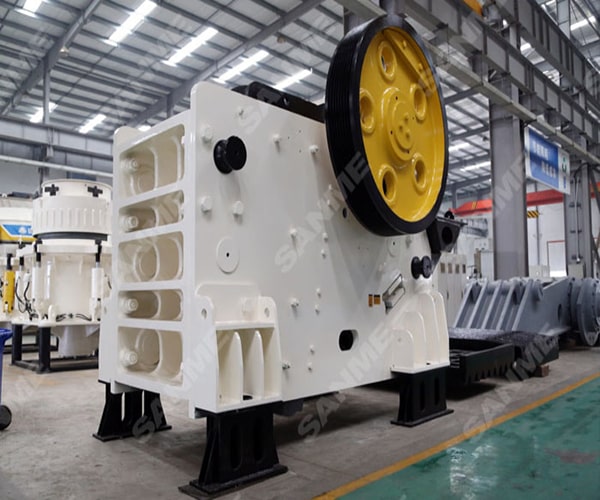

SKJ European Jaw Crusher

Description

SKJ European jaw crusher is widely used in mining, building materials, silicate, metallurgy, road construction, chemical industry raw materials and other fields, especially suitable for crushing medium hardness materials, such as rock, ore, clinker of cement plant,s and so on Applications: various mineral ores and rocks whose anti-pressure does not exceed 280Mpa 100-800 T/HCapacity75-220Power(kW) Product Brief Introduction More advanced movable jaw assembly lengthens the user's life. The movable jaw assembly is composed of high-quality steel casting (weld assembly); the large flywheel (pulley) adopts the block casting process; the heavy eccentric shaft is processed forging. All of the above processes make the SKJ series European Jaw Crusher own overwhelming reliability. An integral cast steel structure is adopted for the bearing seats. The integral bearing seat can fit the frame completely, which not only enhances the radial strength but also reduces the maintenance cost. Bearing with larger specifications and higher bearing capacity is used. Compared with the other series of jaw crushers, the SKJ series European Jaw Crusher adopts larger and more durable bearings. The larger carrying capacity and efficient labyrinth seal lengthen the life span of the bearing dramatically. The Crusher chamber adopts a “V” structure. Symmetric “V” chamber structure design, large angle of toggle plate, large stroke, and optimal revolving speed bring larger feeding size, larger capacity, more evenly particle sizes, and reduced abrasion of jaw plates. Adjustment of the discharge part is more convenient. The discharge opening is adjusted by hydraulic and wedge block type, which makes discharge opening adjustment more convenient and makes maintenance more automatic. This system can reduce downtime obviously when the chamber needs to be cleared for the machine halt caused by power failure. The effective stroke at the bottom of the crushing chamber is larger. The more reasonable of design for the kinetic parameters of the crushing chamber, the more effective stroke at the bottom. The SKJ series adopts higher centrifugal force and a steep inclined angle of toggle plate design. A larger stroke, the appropriate speed, and flywheel inertia ensure better crushing performance. More rational design and more stable performance. The complete machine adopts a modular design, which makes disassembly and transportation more convenient. The raised movable jaw plate can not only protect the movable jaw and bearing chamber but also ensure smooth discharging and realize optimal continuous crushing operations Technical ParametersSKJ European Jaw Crusher

SKJ European Jaw Crusher