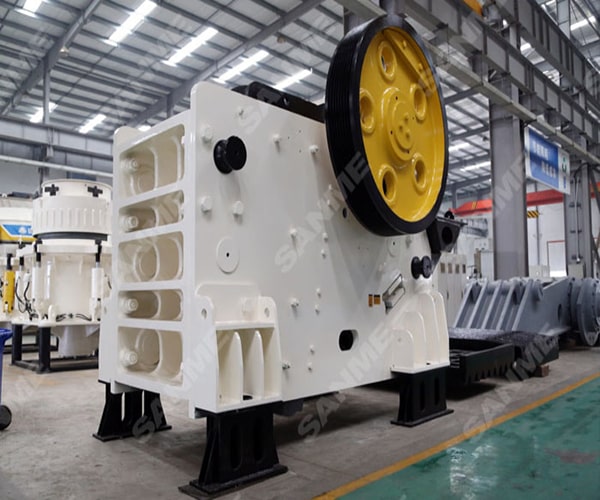

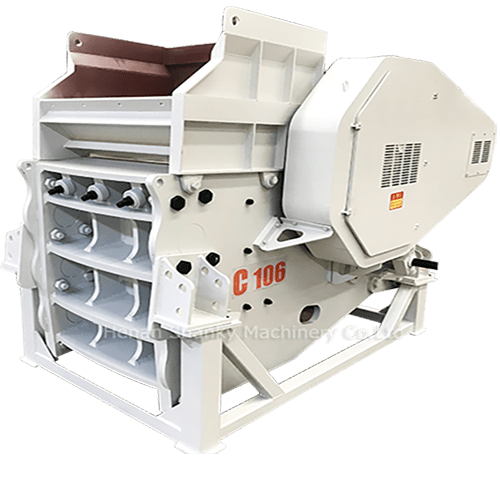

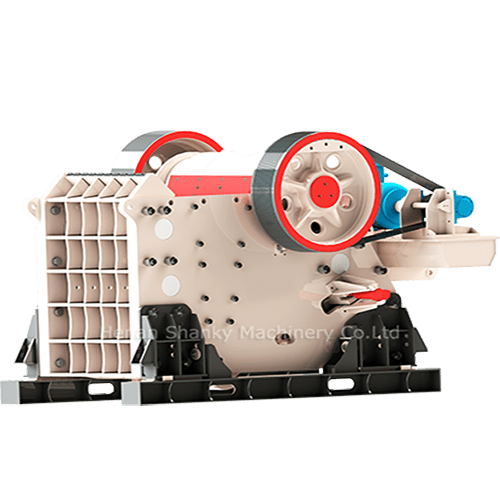

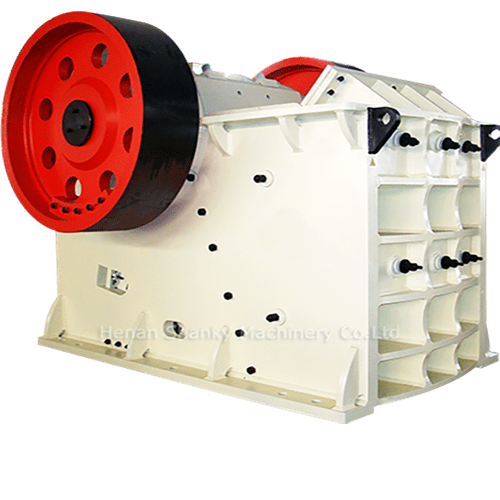

PE/PEX SERIES JAW CRUSHER

Description

PE Series Jaw Crusher is one of the most common crushing equipment. It is mainly applied in crushing the material with compressive strength under 320Mpa. PE Series Jaw Crusher is usually used in the field of mining, metallurgy, road & railway construction, water conservancy, the chemical industry, and so on. The Jaw Crusher of a medium and large size designed and manufactured by our company have reached the advanced level with the features of high crushing ratio, high capacity, uniform product size, simple structure, reliable operation, easy maintenance, and low operation. CAPACITY:10t/h-500t/h MAX FEEDING SIZE: 120mm-1020mm RAW MATERIALS / Limestone, shale, calcium carbide, carbide slag, bluestone, basalt, river pebbles, copper, ore, etc. APPLICATION stone mining, metallurgy industry, building material, highway, railway, chemical, etc. Simple structure, easy maintenance, stable function, low operation cost, great crushing ratio. Deep crashing cavity, no unreachable corner in the cavity, higher feeding capacity, and productivity. Great crushing ratio, homogeneous output size. Discharging adjustment by shim, is reliable and convenient, with a broad range of adjustments, and more flexibility. Safe and reliable lubrication system, easy to change spare parts, less effort in maintenance. Simple structure, reliable work, and low cost in operation. Less energy consumption: one machine can reduce 15%-30% energy consumption, and the whole system can reduce by half. A broad range of discharging adjustment meets variable requirement of customers. Low noise, little dust. APPLICATION OF PE/PEX SERIES JAW CRUSHER PE/PEX Series Jaw Crusher is of single toggle type and used widely in mining, metallurgy, construction, road, railway, hydroelectric, and chemistry. It is suitable for the primary or secondary crush of large rock with compressive resistance of no more than 320MPa. PE is used for primary crushing, and PEX is used for secondary and fine crushing. The main components of the jaw crusher consist of the main frame, eccentric shaft, driving wheel, fly wheel, side protecting plate, toggle, toggle seat, gap adjustment rod, reset spring, fixed jaw plate, and movable jaw plate. Toggle plays the role of protection. WORKING PRINCIPLE OF PE/PEX SERIES JAW CRUSHER Powered by an electrical motor, the movable jaw is set in reciprocate movement at a predetermined track through the transmission system of the driving wheel, Vee-belt, and eccentric roll-driving shaft. The material is crushed in the cavity composed of a fixed jaw plate, movable plate, and side protecting plate, and discharged the end product from the bottom discharge opening. This series jaw crusher adopts a curve-movement compression way to crush the material. The electric motor drives the belt and belt wheel to set the movable plate in moving up and down through the eccentric shaft. When the movable jaw rises, the angle formed by the toggle and movable plate will be wider, and the jaw plate will be pushed approaching the fixed plate. In this way, the materials are crushed through compressing, grinding, and abrading. When the movable plate descends, the angle formed by toggle and movable plate will became narrower. Pulled by rod and spring, the movable plate will move apart from toggle, so the crushed materials can be discharged from the bottom of the crushing cavity. Consecutive movement of motor drives the movable plate in circular crushing and discharge to realize large-quantity production. PRODUCT DATA Technical Data of PE/PEX Series Jaw Crusher:PE/PEX SERIES JAW CRUSHER

FEATURES AND TECHNOLOGY ADVANTAGES OF PE/PEX SERIES JAW CRUSHER

CONFIGURATION OF PE/PEX SERIES JAW CRUSHER