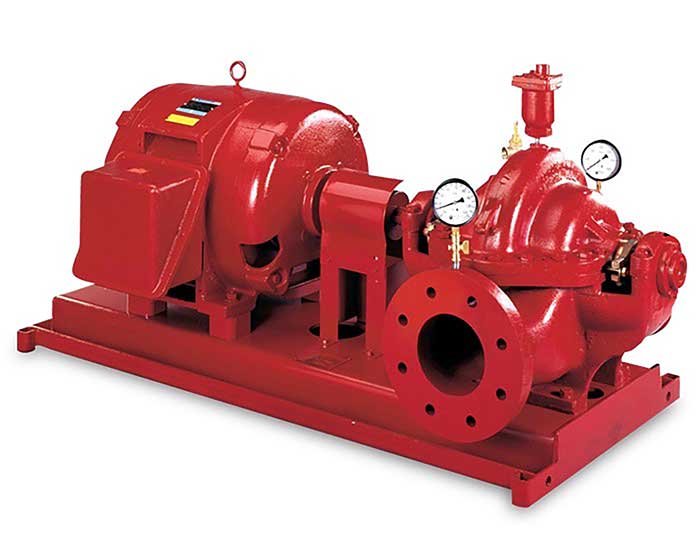

HORIZONTAL SPLIT CASE FIRE PUMPS

Description

Applications Features & benefits General Pump Features 1 – Impeller & Casing 2 – Shaft 3 – Bearing 4 – Seal 5 – Casing

The FGHC fire pumps are used in fire-fighting applications for supplying water to fire hose reels, fire hydrants or sprinkler systems in areas which are prone to the hazards of fire.

The typical applications are as follow:

• Commercial complexes and high rise buildings

• Petrochemical industries and Gas plants

• Oil and Gas on-shore &off-shore platforms

• Oil terminals

• Airports and ports

• Jetties

• Marine applications

• Power stations and transformer stations

• Chemical industries

• Manufacturing plants

• Fire-work industries

• Warehouses/godowns.

FGHC fire pumps offers all features & benefits as mentioned in our GHC standard pump series data booklet. Following are the additional features & benefits offered by these pumps :

• State-of-the-art design fire pumping system.

• UL listed/FM approved/NFPA-20 design

• Diesel engine as well as electric motor driven pump

• Rugged construction

• Liberal water passages

• Automatic air relief valve

• Efficient operation

• Lower initial cost

• Reduced installation time and cost

• Simplified piping design

• Suitable for space saving installation systems and retrofit applications

• Easy access to all working parts

• Ease of maintenance

• Single source unit responsibility.

• Minimal axial thrust due to double-entry impeller.

• Impeller is dynamically balanced to grade G6.3 balance quality in accordance to ISO 1940-1.

• Impeller & Casing are designed using state of art CFD tools to ensure optimal performance.

• Heavy duty stainless steel shaft completely sealed and dry for zero corrosion.

• Short and rigid with negligible vibrations.

• Replaceable shaft protecting sleeves.

• No threads exposed to pump medium, long operating life and no corrosion.

• Adjustment-free assembly.

• Heavy duty and grease lubricated antifriction bearings for long service life.

• Open gland, enough space for service activities.

• Asbestos – free, soft packed stuffing boxes.

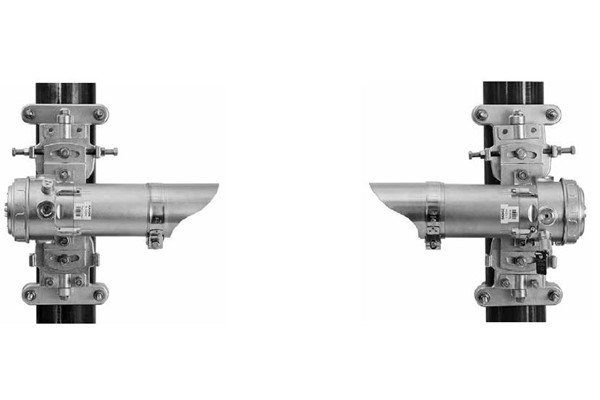

• In-line axially split design which permits removal of the complete Impeller Shaft Assembly without removing the pipes & motor.

• Short distance between bearings.

• Leak-tight due to compact joint flange with long Pre-stessed bolts.

• Counter-rotation possible with similar parts.

• Easy mounting self-aligning upper casing.

• Flange drilled as per ANSI B16.1 class 250.

• Smooth surface inside & CED coated for superior corrosion protection.

• Replaceable wear ring protect the casing and the impeller running clearances.

• Heavy duty casing design for high working pressure.